Pin 19, Fig. 65, provides the charging

voltage for the memory capacitor. The

voltage at pin 19 should go more positive

as you set faster shutter speeds on

manual or as you increase the light level

on automatic. The same voltage appears

at pin 10. Pin 10 couples the memorized

reference voltage from the memory

capacitor to the current-control circuit

that charges the timing capacitor.

A t pin 9, you should see a OV signal un

til you release the shutter. The voltage

then swings positive to negative (OV) to

turn on T13.

You can check switching actions at the

other pins. For example, pin 12 connects

to the trigger switch. W ith the shutter

cocked, you should measure OV at pin 12;

the closed trigger switch then connects

pin 12 to ground. However, you should

measure around 1,3V during the exposure

when the trigger switch opens. W hat if

you don't? If the voltage stays at OV,

suspect a problem w ith the trigger

switch.

Another switch — S11 of the mode

switch — connects to pin 11. If the shut

ter delivers only the mechanical exposure

in all modes, you might check the pin 11

voltage. You should see the voltage

change as you move the mode switch

from the S position to the A position. If

not, suspect poor contact in S11.

As another example, S9 of the mode

switch connects to pin 20. Here, you

should see a voltage change as you go

from the M mode to the A mode. Poor

contact in S9 could cause the shutter to

hang open in all modes. Fig. 66 points out

the mode-switch paths that correspond

to S8, S9, S11, and S13.

MODIFICATION TO THE

TIM IN G CIRCUIT

You may recall the symptom of a

shorted memory capacitor C2 — the shut

ter hangs open on all modes. W ith no

voltage across the memory capacitor,

transistor #1, Fig. 64, has no base drive.

Consequently, it can't charge the timing

capacitor. The same symptom may result

from poor contact in the memory switch.

Similarly, under very low light condi

tions, there's a low voltage across the

memory capacitor. If you operate the

camera at one of the automatic settings in

complete darkness, the shutter hangs

open until the batteries die. You can, of

course, remove the batteries to close the

shutter. But Minolta discovered that

owners were going through batteries by

letting their shutters hang open.

A t the current price of silver-oxide bat

teries, Minolta felt the problem deserved

a modification — a modification that

allows the timing capacitor C3 to event

ually charge. Minolta suggests adding a

large-value resistor — 50 megohms — be

tween pin 14 of IC1 (ground) and the

negative lead of C3, Fig. 55.

The large resistor has no effect on the

normal operation. However, it allows the

timing capacitor to eventually charge and

close the shutter. You may have some

trouble locating a 50M resistor that's

small enough in size. Fortunately, Minolta

does supply the resistor through their

parts department;

it's part number

9431-1078-31.

REPAIRING AND ADJUSTING

THE COMBINATION MAGNETS

W e've already described the trouble

shooting steps to detect an open coil in

either M1 or M2, Fig. 63. Remember, an

open M1 coil prevents the mirror from

releasing. If M2 has an open coil, the

diaphragm always stops down fully in the

S mode.

However, you may also encounter

mechanical problems w ith the combina

tion magnets. Dirt causes one such prob

lem. For example, dirt between the M1 ar

mature and the magnet core prevents the

magnetic attraction. As a result, the mir

ror releases as soon as you complete the

cocking stroke.

Dirt can cause a similar problem w ith

the M2 magnet. If M2 fails to hold its ar

mature, the diaphragm can't stop down.

The armature arrests the ratchet gear as

soon as the diaphragm starts to close.

Minolta has improved both the M1

magnet and the M2 magnet to minimize

the dirt problem. In the newer designs,

the armature moves a rod w ithin a hole.

The hole serves to seal both the armature

and the core from dirt.

Incorrect adjustments cause similar

problems. But you normally don 't have to

adjust the magnets — not unless you've

replaced either M1 or M2. If you replace a

magnet, you'll have to adjust its position.

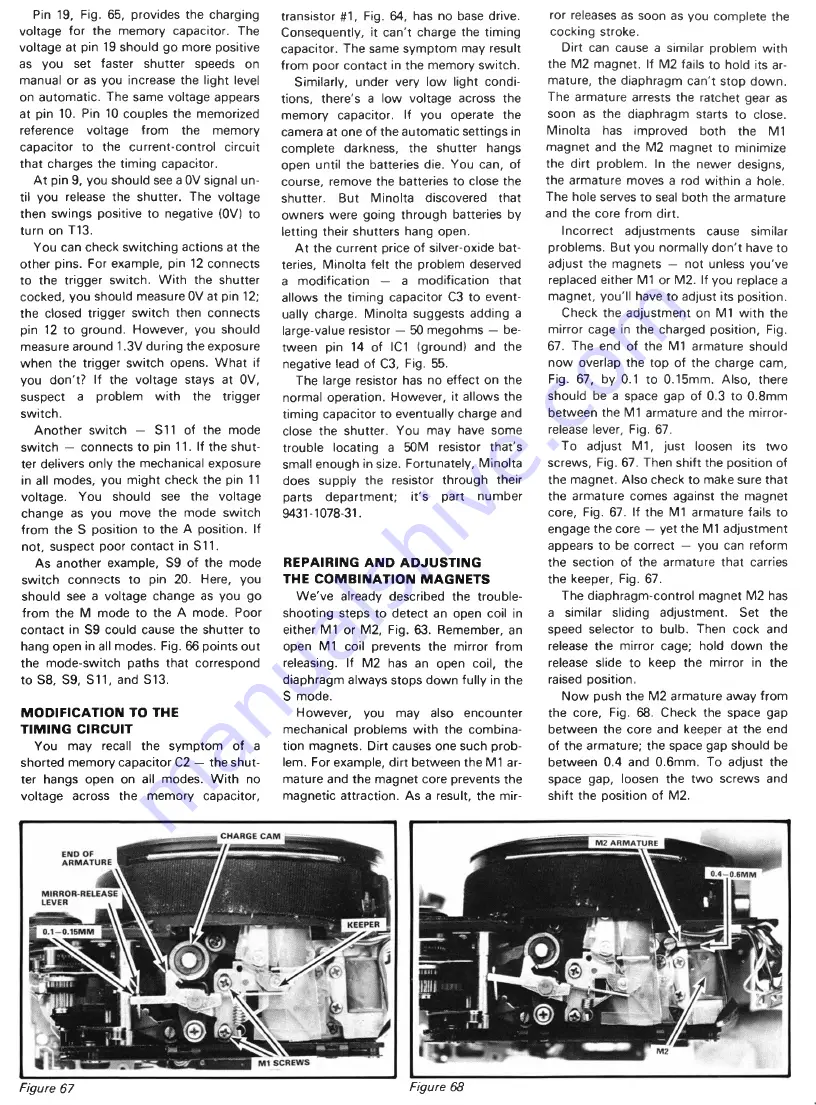

Check the adjustment on M1 w ith the

mirror cage in the charged position, Fig.

67. The end of the M1 armature should

now overlap the top of the charge cam,

Fig. 67, by 0.1 to 0.15mm. Also, there

should be a space gap of 0.3 to 0.8mm

between the M1 armature and the mirror-

release lever, Fig. 67.

To adjust M1, just loosen its tw o

screws, Fig. 67. Then shift the position of

the magnet. Also check to make sure that

the armature comes against the magnet

core, Fig. 67. If the M1 armature fails to

engage the core — yet the M1 adjustment

appears to be correct — you can reform

the section of the armature that carries

the keeper, Fig. 67.

The diaphragm-control magnet M2 has

a similar sliding adjustment. Set the

speed selector to bulb. Then cock and

release the mirror cage; hold down the

release slide to keep the mirror in the

raised position.

Now push the M2 armature away from

the core, Fig. 68. Check the space gap

between the core and keeper at the end

of the armature; the space gap should be

between 0.4 and 0.6mm. To adjust the

space gap, loosen the tw o screws and

shift the position of M2.

Figure 67

Figure 68