ing the metering switch S5. Next the

brush connects the orange-wire contact

to ground to close the release switch S3.

As noted during the troubleshooting,

suspect S5 if pushing the release button

part way fails to turn on the LED display.

Suspect S3 if the shutter w o n 't release at

the electronic settings. You can now

clean the brush contact and the sw itch

board lands.

But, if you remove the switches for

cleaning, you'll have to readjust the switch

board. Adjust the switch timing by first

loosening the tw o screws — one holding

the brush and one holding the switch

board, Fig. 101. Then shift the position of

the switch board to set the amount of

release-slide movement needed to close

each switch.

Check the metering switch S5 first.

Connect an ohmmeter between the green

wire and ground. Then slowly depress the

release button. When the release slide

moves down 0.4mm, the metering switch

should close. Your ohmmeter should

then show direct continuity between the

green wire and ground.

To check the release switch, make sure

you've set the speed knob to an electronical

ly controlled speed. Then connect your ohm

meter between the orange wire and ground.

The release switch should close when the

release slide moves down 1 mm.

Double-check the switch timing by set

ting a mechanical speed — 0 or B. The

release-slide latch now moves out of the

path of the release slide. As the brush

starts to rotate clockwise, the release-slide

latch blocks the switch arm, Fig. 101.

The brush should still rotate far enough

to close the metering switch. However,

the release-slide latch should block the

brush rotation before the release switch

closes.

So, w ith your ohmmeter connected

between the orange wire and ground,

depress the release button. The release

switch should not close — no matter how

far down the release slide moves. Then

check the metering switch between the

green wire and ground. The metering

switch should close when the release

slide moves down 0.4mm.

REMOVING THE FLEX CIRCUIT

Other than for replacement purposes,

there aren't too many reasons to remove

the flex circuit. The complete flex circuit

does come as a replacement part (flexible

circuit base plate, A set — 0841). A

replacement flex includes the RTV

(shutter-speed) resistor, but not the

diaphragm resistor or the SPD board.

There's also an exchange program. If you

send in the old flex circuit, you can get

the replacement for about half price.

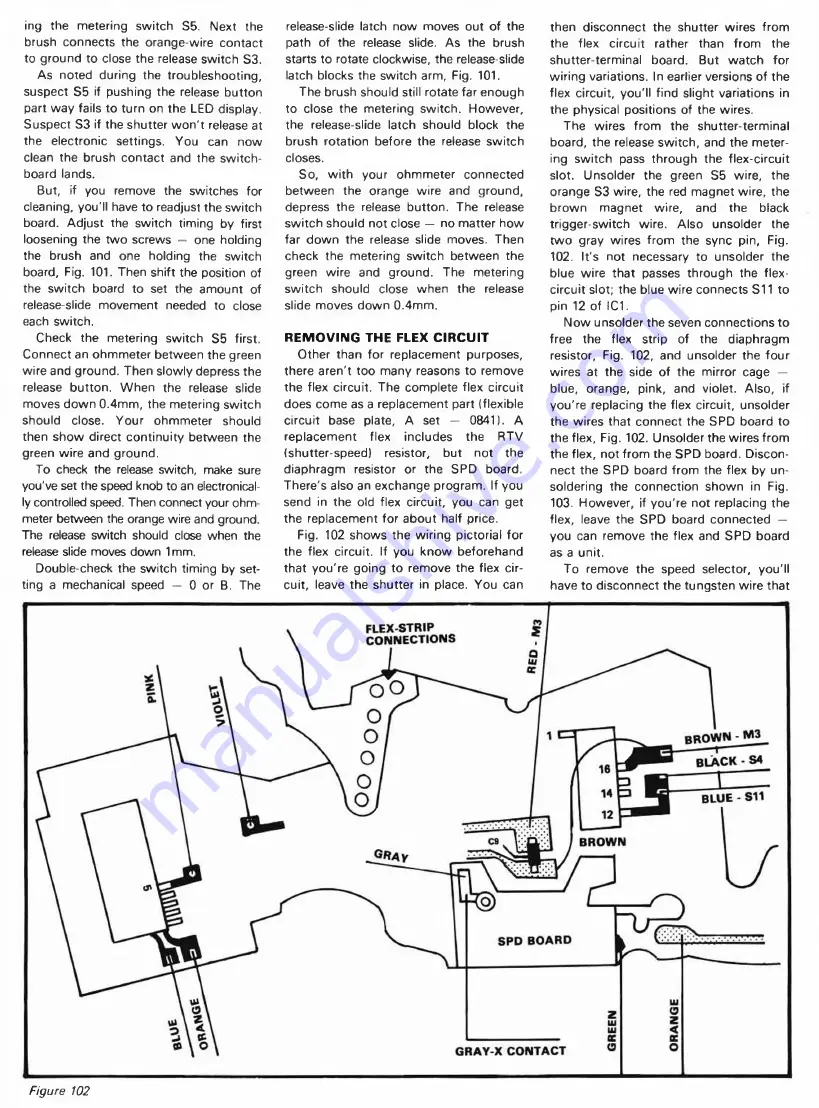

Fig. 102 shows the wiring pictorial for

the flex circuit. If you know beforehand

that you're going to remove the flex cir

cuit, leave the shutter in place. You can

then disconnect the shutter wires from

the flex circuit rather than from the

shutter-terminal board. But watch for

wiring variations. In earlier versions of the

flex circuit, you'll find slight variations in

the physical positions of the wires.

The wires from the shutter-terminal

board, the release switch, and the meter

ing switch pass through the flex-circuit

slot. Unsolder the green S5 wire, the

orange S3 wire, the red magnet wire, the

brown magnet wire, and the black

trigger-switch wire. Also unsolder the

tw o gray wires from the sync pin, Fig.

102. It's not necessary to unsolder the

blue w ire that passes through the flex-

circuit slot; the blue wire connects S11 to

pin 12 of IC1.

Now unsolder the seven connections to

free the flex strip of the diaphragm

resistor, Fig. 102, and unsolder the four

wires at the side of the mirror cage —

blue, orange, pink, and violet. Also, if

you're replacing the flex circuit, unsolder

the wires that connect the SPD board to

the flex, Fig. 102. Unsolder the wires from

the flex, not from the SPD board. Discon

nect the SPD board from the flex by un

soldering the connection shown in Fig.

103. However, if you're not replacing the

flex, leave the SPD board connected —

you can remove the flex and SPD board

as a unit.

To remove the speed selector, you’ ll

have to disconnect the tungsten wire that

FLEX-STRIP

C O N N E C TIO N S

B R O W N - M 3

B L A C K - S4

SP D B O A R D

G R A Y -X C O N T A C T

Figure 102