10

PROGRAMMING

PCB-001-388

REVISION A (09/2017)

Fault Resolu4on

2.

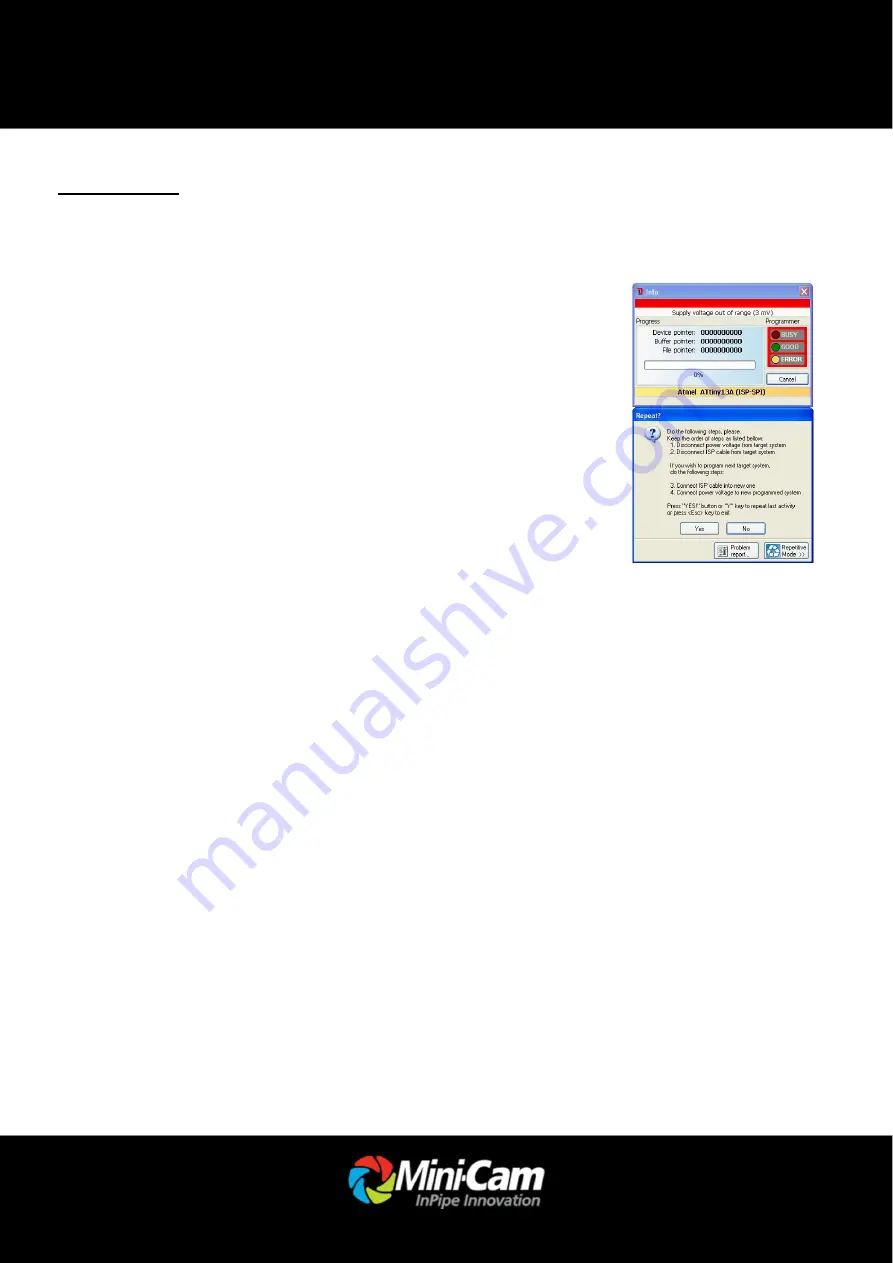

Supply voltage out of range (3mV)

This fault will occur if voltage is not supplied to the on board microcontroller.

There is more than one reason this could happen…

•

12v is not being supplied to the jig.

Ensure the power supply is set to 12v with the output on and is connected to the jig

properly.

•

Connec on not made/maintained between PCB & pogos

Ensure enough pressure is applied to the PCB for the dura on of the programming

process, refer to the ‘Board Power’ LED on the jig, it will light up when a connec on

is made between the PCB & pogos.

If the problem has not yet been resolved there is a further possibility…

•

Faulty on board component/components

Although it is rare it is not impossible the problem is being caused by an on board problem, the input supply has

to pass through components before it powers up the microcontroller. If an on board fault is preven ng the

microcontroller from being powered up, it cannot be programmed.

If the problem is s ll not yet resolved reject the device to the relevant personnel in the PCB

department.

PAGE 8