21

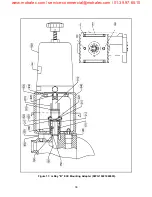

There a re three leve ls o f calibration th at ca n b e

performed. Use the appropriate calibration routine

for you r requirement. For a ll r outines, reference

Figure 10.

4.8.1.1 Calibration A

Calibration A is performed to synchronize the ECC

with the pump. Calibration A is performed when:

•

Replacing any components in the position

feedback assembly. This includes the

nylon worm gear/driver, the potentiometer,

and/or the potentiometer gear.

•

Adding or removing reverse action jump-

ers (Section 3).

1. Tools needed for calibration A:

a) Digital volt meter (DVM) or equivalent with

resistance, 5 VDC, and 20 mA.

b) 4-20 mA (1-5 VDC) source and 115 or 220

VAC source

c) Precision screwdriver to a djust potentiom-

eters

Figure 14. Potentiometer Connector P2 Pins 1

and 2

d) Tool kit

2. Preparation:

a) All new components should be replaced.

b) Insure pump is set to 0% setting.

c) Remove AC power.

d) Remove cover from ECC.

VOLTAGE SELECTOR SWITCH

SW1

LOCATED ON TOP OF THE CIRCUIT

BOARD MUST BE SET TO THE VOLT-

AGE LISTED ON YOUR DATA PLATE

(FIGURES 1 OR 2) , OR DAM AGE TO

MOTOR WILL RESULT.

e) Ensure voltage selector switch is set to 115

VAC or 230VAC as indicated on data plate

(Section 2).

f) If circuit board has be en replaced ensure

DIP switche s SW2 and SW3 are set as

needed for proper operation (Section 2).

g) Remove ECC from pump.

3. Remove PCB (Paragraph 4.4.1) to gain access

to feedback potentiometer.

4. Remove P2 and connect DVM between P2 pin

1 and P2 pin 2 (Figure 14). Loosen screws to

potentiometer to allow movement of potentiom-

eter gear without moving nylon worm gear. Set

potentiometer to 1.5K ohms ±100 ohms for Mil-

royal B, C, and Macroys, 0.87 ohms ±0.1 ohms

for mRoys a nd 1 .3 oh ms ±0 .1 ohm s for

Maxroys and Milroyal D E CCs and re-tighten

potentiometer screws. This sets the resistance

of the potentiometer.

5. Install PCB ( Paragraph 4 .4.2) a nd pe rform

remaining adjustments.

www.motralec.com / [email protected] / 01.39.97.65.10