19

WARNING

ALWAYS DISC ONNECT ELECTRICAL

POWER FROM THE PUMP MOTOR AND

ECC B EFORE PE RFORMING A NY

MAINTENANCE. FAILURE TO FOLLOW

THESE INSTR

UCTIONS COULD

RESULT IN DEATH OR SER

IOUS

INJURY.

2. Disconnect power from ECC.

3. Remove PCB (Paragraph 4.4.1).

4. Remove fee dback potentiometer ( Paragraph

4.5.1).

5. Remove screw that se cures c apacitor (6 5) (i f

installed) to ECC . Slid e ca pacitor to on e s ide

away from nylon worm gear (190). Leave wires

attached.

6. Using a 3/32 punch, push out spring pin hold-

ing nylon gear on shaft. Remove gear.

4.6.2 Installation of Nylon Worm Gear

1. Slide ne w n ylon wor m ge ar (1 90) over moto r

shaft and align shaft holes to gear holes with 3/

32 punch. Being careful not to da mage nylon

worm ge ar, pr ess sp ring pin (2 00) thr ough

holes in gea r a nd shaft. Pla ce pin eq ual d is-

tance from both sides of gear.

2. Reinstall c apacitor (6 5) ( if r emoved). T ighten

screw. Do not allow wires to be pinched under

capacitor.

3. Install feedback potentiometer (Paragraph

4.5.2).

4. Install PCB (Paragraph 4.4.2).

5. Perform calibration A.

4.7 MOTOR REPLACEMENT

4.7.1 Removal of Motor

1. Apply power and set pump stroke adjust knob

to 0% settin g or remove power and manually

turn the pump stroke adjust knob to 0% setting.

WARNING

ALWAYS DIS CONNECT ELECTRICAL

POWER FROM THE PUMP MOTOR AND

ECC BEFO RE PER FORMING AN Y

MAINTENANCE. FAILURE TO FOL LOW

THESE INSTR

UCTIONS COULD

RESULT IN DEATH

OR SE RIOUS

INJURY.

2. Disconnect power from ECC.

3. Disconnect ECC fro m pum p. Remove four

bolts/screws that mo unt ECC to br acket an d

carefully remove ECC from pump.

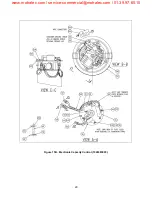

4. Disconnect gea r bo x (mRo y A and B has no

gear box) from ECC. Remove four screws that

mount gear box to ECC a nd carefully remove

gear box from ECC.

5. Clean grease from gea r located at bottom of

motor sha ft. Using a 1 /8 pu nch p ush o ut

spring pin holding gear and slide gear off shaft.

Retain gear and spring pin. Parts will be used

during installation of new motor.

6. On mRoy A and B ECCs use a 3/16 punch and

push o ut spr ing pin ( Figure 16 a nd 17, item

920) ho lding dr ive shaf t ( 910). Remo ve dr ive

shaft. Retain drive shaft and spring pin. Parts

will be used during installation of new motor.

7. Remove PCB (Paragraph 4.4.1, Steps 4-6).

8. Lossen two screws for feedback potentiometer

and slide potentiometer away from worm gear.

9. Note p lacement o f wir ing to J1 for ide ntical

placement during inst allation of new moto r.

Remove two cable ties fro m connector J1 wir-

ing.

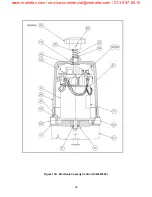

10. Carefully remove two screws (Figure 15, item

140) from ad apter plate ( 60) and remove

adapter plate from motor.

11. Remove motor wires from J1.

12. Remove four mounting screws (50) from bot-

tom of base (10) and remove motor.

www.motralec.com / [email protected] / 01.39.97.65.10