17

SECTION 4

MAINTENANCE

4.1 SPARE PARTS

To avoid delays in repairs, the following spare parts

should be stocked for your ECC:

NOTE

See Par agraph 2.1 .2 and 2.1.3 b efore

ordering circuit boards.

Circuit Board - - - - - - - - - - - - - - 30300/39320

NOTE

When o rdering Potentiometer As sy or

Motor a lso or der jump er wir es. Jumper

wires are used when older wiring does not

match the color coding of the new parts.

3 wire jumper - - - - - - - - - - 0152173200

Nylon Worm Gear - - - - - - - - - Call Factory

Motor - - - - - - - - - - - - - - - - - - Call Factory

5 wire jumper - - - - - - - - - - 40229

Parts orders must include the following information:

Pump serial number (on pump nameplate)

Model number (on ECC nameplate)

Part description

Quantity required

Always include the serial and model numbers in all

correspondence regarding the unit.

4.2 RETURNING UNITS TO THE FACTORY

Electronic Capacity Control (ECC) units will not be

accepted fo r r epair without a Return Material

Authorization, availab le fro m th e Factor y Repair

Department. If the ECC is being returned attached

to a p ump, process liquid should be flushed from

the pump liquid end and oil should be drained from

the pump ho using be fore the pu mp is sh ipped.

Label the un it clear ly to indicate the liquid being

pumped.

NOTE

Federal la w pr ohibits handling of eq uip-

ment that is not accompanied by an OSHA

Material Sa fety Dat a Sheet (M SDS). A

completed MSDS must b e packed in th e

shipping crate if the ECC is

returned

attached to a p ump. These safety precau-

tions will aid the troubleshooting and repair

procedure a nd p reclude serious inju ry to

repair personnel from hazardous residue in

pump liquid end.

All inquiries or parts orders should be addressed to

your local Milton Roy representative or send to:

Parts Department

Milton Roy Company

Flow Control Division

201 Ivyland Road

Ivyland, PA 18974-0577

Phone: (215)-441-0800

Fax: (215)-441-8620

4.3 MAINTENANCE

Because o f it s so lid-state de sign, th e Milton Ro y

ECC is e xceptionally re liable an d sho uld se ldom

need main tenance or r epair. Aside fro m calibr a-

tions (the u nit is calib rated at the factor y and

should not need calibrated initially), the only typical

maintenance p rocedures ar e r eplacement of the

printed cir cuit board, feed back potentiometer,

nylon worm gear, and/or replacement of the motor.

4.4 PRINTED CIRCUIT BOARD (PCB) RE-

PLACEMENT

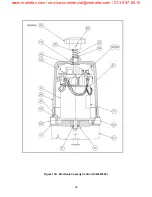

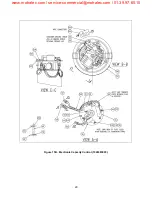

4.4.1 Removal of PCB (Figure 15)

1. Apply power and set pump stroke adjust knob

to 0% se tting or remove power and manually

turn the pump stroke adjust knob to 0% setting.

WARNING

ALWAYS DIS CONNECT ELECTRICAL

POWER FROM THE PUMP MOTOR AND

ECC BEFO RE PER FORMING AN Y

MAINTENANCE. FAILURE TO FOL LOW

THESE INSTR

UCTIONS COULD

RESULT IN DEATH

OR SE RIOUS

INJURY.

2. Disconnect electrical power to ECC.

www.motralec.com / [email protected] / 01.39.97.65.10