20

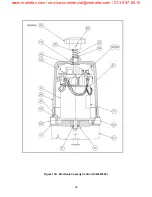

4.7.2 Installation of Motor

1. Mount motor to base (10) and secure with four

mounting screws (50).

2. Connect motor wires to J1.

3. Remove wo rm ge ar (1 90) fr om o ld m otor.

Carefully r emove spring p in (200) w ith 3/ 32

punch without damage to worm gear (190).

4. Slide wo rm ge ar (190) o ver ne w mo tor sh aft

and a lign sha ft h oles to ge ar hole s. Bein g

careful not to damage nylon worm gear, press

spring pin ( 200) through holes in g ear a nd

shaft with 3/32 punch. Place pin equal distance

from both sides of gear.

5. Attach adapter plate (60) to motor and secure

with two screws (140). O ne screw (140) also

mounts capacitor (65) to adapter plate.

6. Apply a very small amount of lithium grease (if

needed) to motor shaft nylon worm gear. Motor

shaft may have grease from previous mainte-

nance.

7. Reposition feedback potentiometer (Paragraph

4.5.2, Steps 1 & 2).

8. Position wirin g to J1 a s noted p reviously an d

attach two cable ties.

9. Install PCB (Paragraph 4.4.2, Steps 1 and 2).

10. On mRoy A and B ECCs slide drive shaft (Fig-

ure 16 and 17, item 910) over bottom of motor

shaft an d align mounting ho les. Pre ss sp ring

pin (920) through both holes with 3/16 punch.

Place pin equ al d istance from both sides of

gear.

11. Slide gear removed previously from bottom of

motor shaft over new mo tor shaft. Align shaft

holes to gear holes. Being careful not to dam-

age ge ar, pr ess spring pin th rough holes in

gear and shaft with 1/8 punch. Place pin equal

distance from both sides of gear.

12. Apply lithium grease to gear above and mount

gear box to ECC with four screws (mRoy A and

B has no gear box).

13. Mount ECC to pump. Connect ECC to pump

bracket with four bolts/screws.

14. Connect power to ECC.

15. Perform calibration A.

4.8 ECC CALIBRATION

WARNING

YOU WILL BE MAKING ADJUSTMENTS

TO THE ECC

CONTROL CIRC UIT

BOARD WHILE IT IS POWERED UP.

THIS CONTROL BOAR D IS POWER ED

BY POTEN

TIALLY

DANGEROUS

VOLTAGE (1 15 OR 230 V AC). THE

CALIBRATION PROCED URE IS TO BE

PERFORMED ONLY BY QUAL

IFIED

PERSONNEL FAMILIAR WIT

H THE

HAZARDS INHERENT WORKING NEAR

HIGH VOLT AGES. MILTON ROY

ASSUMES NO RESPONSIBILITIES FOR

DAMAGE TO EQUIPMENT OR INJU RY

TO P ERSONNEL WH ILE PER FORMING

THIS CALIBRATION PROCEDURE.

NOTE

ECCs ar e ca librated at the fa ctory and

usually do no t ne ed to be calibrated ini-

tially.

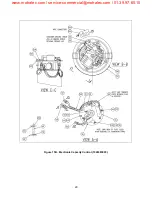

4.8.1 Calibration Routines

The Milton Roy ECC has nine adjustment potenti-

ometers. Th ese p otentiometers adjust the ECC's

span and zero travel, lower and upper travel limits,

feedback ze ro, feed back sp an, contr ol of fset,

range of fset, an d feed back of fset. Co ntrol of fset,

range of fset, and feedback offset will only be

adjusted d uring a co mplete calibr ation pr ocedure

(calibration C). These three adjustments are usally

not changed.

Before calibration is pe rformed set-up the voltage

selector switch , SW1(Paragraph 2 .6.4), input sig-

nal SW2(Pa ragraph 2.6.2) , and feed back ou tput

signal SW3( Paragraph 2 .6.3).

Use o f t he fe ed-

back out put signa l is opt ional and needs set

only if it will be used.

www.motralec.com / [email protected] / 01.39.97.65.10