R410A All DC Inverter V5 X Series 50Hz

MCAC-VTSM-2015-10

116 Installation

No.

Phase (phase-in pressurization)

Criteria

1

Phase 1: large leakage after over three minutes of pressurization with 3.0kgf/cm

2

.

No pressure drop

after modification

2

Phase 2: major leakage after over three minutes of pressurization with 15. 0kgf/cm

2

.

3

Phase 3: small leakage after over 24 hours of pressurization with R410A: 40.0kgf/cm

2

.

10.2.2 Pressure observation

1. System pressure should be maintained for 24 hours. When pressure change is related to temperature

change according to below calculation, it means there are on leakage. If pressure falls, identify and address

the leakage source.

2. Modification method

When ambient temperature difference is ±1°C, the pressure difference shall be ±0.1kgf/cm

2

.

Modification formula: Real value = pressure of pressuri (temperature of pressurization

– temperature

during observation)x0.1kgf/cm

2

A pressure drop can be identified by comparing the modification value with pressurization value.

3. General method for identifying the source of a leak

Detection process involves three general steps.

1) Audio detection for identifying large leaks.

2) Touch detection -----place hand at the joint to feel the leakage

3) Soap water detection is used to identify small leaks. Escaping gas will create bubbles at the leak point after

soapy water is applied.

4) Detection by use of halogen leak detector

Use a halogen leak detector when finding the source of difficult to detect leakages.

a. Keep nitrogen at 3.0kgf/cm

2

.

b. Supplement refrigerant to 5.0kgf/cm

2

.

c. Use halogen leak detector, methane leak detector and electric leak detector for detection.

d. If the leak source cannot be found, continuously pressurize to 40.0kgf/cm

2

(R410A) and then detect again.

4. Caution

1) The air tightness test is conducted by pressurized nitrogen (R410A system: 40.0kgf/cm

2

).

2) Oxygen, flammable gas and toxic gas shall not be used to conduct air tightness test.

3) Before pressure reading, let the system rest for several minutes till pressure is stable.

4) After test is complete, reduce system pressure to 5~8kgf/cm

2

and then conduct pressure-keeping and

storage.

5) If pipeline is too long, conduct phase-in detection.

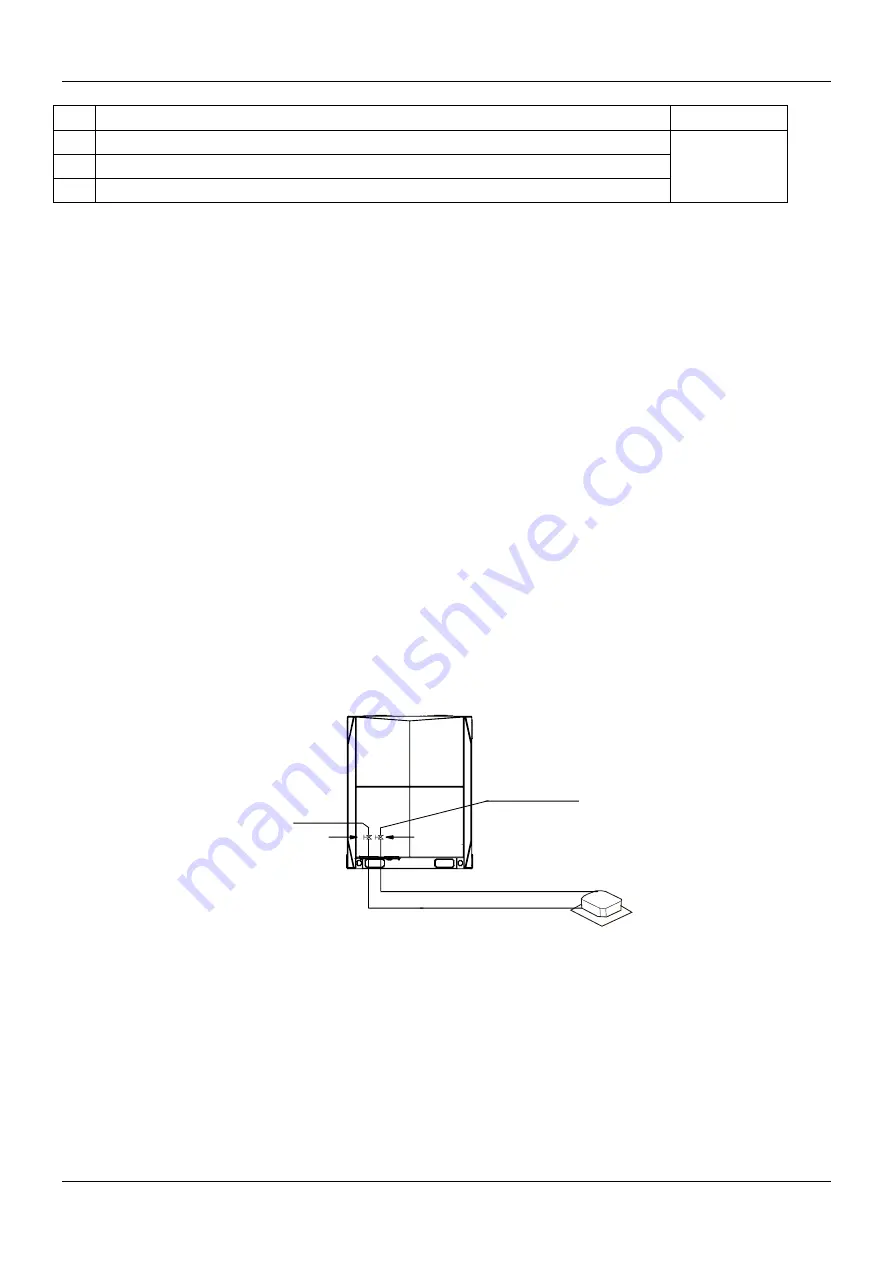

a. Inner side of pipeline

b. Inner side of pi upright

c. Inner side of pi outer side of pipeline

Outdoor unit

Indoor unit

Nitrogen

Liquid pipe

Gas pipe

Liquid side

shut-off valve

Gas side hut-off valve