44 |

U s e r ´ s a n d i n s t a l l a t i o n m a n u a l

D R Y S I R E N

P a g e 4 4 o f 6 8

V e r s i o n : 0 1 / 2 0 1 8

SW

IM

M

IN

G

P

O

O

L

D

EH

U

M

ID

IF

IE

R

DR

Y

S

IR

E

N

a.

Check that each tube (both suction and discharge) between the ceiling and

compressor units have been properly connected and all wiring for the test run has

been completed.

b.

Remove the service valve caps from the suction side on the compressor unit. Please

note that both the suction and the discharge side service valves on the compressor

unit are kept closed at this stage.

2.

Vacuum test

a.

With a service valve wrench (imbus wrench), turn the suction and discharge valve

counter-clockwise to fully open both valves.

b.

Connect the charge hose end described in the preceding steps to the vacuum pump

to evacuate the piping. Confirm the “Lo” knob of the manifold valve is open. Then,

run the vacuum pump. The operation time for evacuation varies with tubing length

and capacity of the pump. The following table shows the time required for

evacuation when using a vacuum pump of 30 gal/h power.

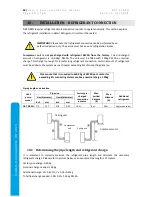

Required time for evacuation when 30 gal/h vacuum pump model is used

Tube length less than 10m

Tube length more than 10m

Minimum 20 minutes

Minimum 30 minutes

c.

When the desired vacuum is reached, close the “Lo” knob of the manifold valve and

stop the vacuum pump.

d.

Close the valve on charging hose at vacuum pump.

3.

Refrigerant filling

a.

Now remove the vacuum pump and bring the refrigerant bottle and charging scales.

Connect the disconnected hose (point d above) to refrigerant bottle (liquid side).

Place the bottle on charging scales and turn the scales on. Please make sure no

object, pipe, cable or other touches the bottle or charging scales. Otherwise weight

misreading may occur.

b.

Please close the valve at hose at suction side of compressor unit.

c.

Open the manifold ‘Lo’.

d.

Open the valve at hose at refrigerant bottle.

e.

Open the bottle’s valve.

f.

Zero the charging scales out.

g.

Open the valve at hose at suction side of compressor unit. Please mind that the

compressor unit is still off.

h.

Wait until the unit sucks necessary amount of refrigerant. Charging scales typically

shows the weight as negative number (how much was taken out from the bottle).

i.

Sometimes the necessary amount of refrigerant is not sucked into the system by

itself. The reason can be:

room air temperature / bottle temperature too low

Low bottle pressure (low amount of gas in bottle)

Restriction in copper pipes