38 |

U s e r ´ s a n d i n s t a l l a t i o n m a n u a l

D R Y S I R E N

P a g e 3 8 o f 6 8

V e r s i o n : 0 1 / 2 0 1 8

SW

IM

M

IN

G

P

O

O

L

D

EH

U

M

ID

IF

IE

R

DR

Y

S

IR

E

N

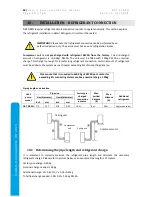

9.

DRAINAGE OF CONDENSATE WATER

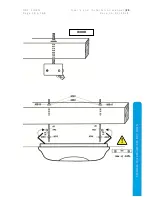

Condensed water is pumped from the unit upwards with total vertical discharge of 40cm (netto out

of the unit 20cm) and then by the force of gravity (downwards). Unit’s condensate tray is levelled to

have sufficient declivity when the ceiling unit is perfectly levelled (using spirit level) with tolerance

+/- 0.3%. Compressor unit uses only the force of gravity. The condensation water must be drained

through

a siphon

into a municipality sewage system or into the outside environment. Please do not

place the drainage hose upwards (against gravity); this will lead in unit’s inability to drain the

condensate water. This will subsequently cause water leakage from underneath the unit’s cover and

may lead to unit’s malfunction, damage or failure. Also it may cause the underlying floor be wet,

which creates danger of accident and harm to health resulting from unwanted slip. Manufacturer,

distributor or reseller are not responsible for such damages.

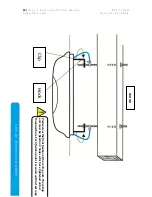

Incorrect drain installation.

Avoid ‘waving’. Accumulated water in downslope

‘waves’ avoids normal condensate drain and will

result in water leakage.

Incorrect drain installation.

Do not increase the drain after it was in

downward slope.

Do not drink the condensate water. Do not pour or let the condensate water back

to the swimming pool. It may be contained with bacteria.

Downward slope.

max. 200mm

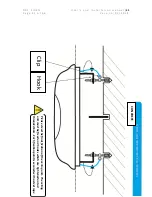

Siphon.

TR8

Fix the condensate drain

onto the TR8.