D R Y S I R E N

U s e r ´ s a n d i n s t a l l a t i o n m a n u a l

|

43

P a g e 4 3 o f 6 8

V e r s i o n : 0 1 / 2 0 1 8

SW

IM

M

IN

G

P

O

O

L

D

EH

U

M

ID

IF

IE

R

D

R

Y

S

IR

E

N

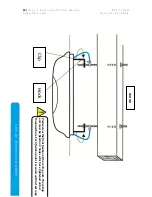

When cutting the pipes and cables, please mind the following:

1. Measure the distance between the water and the condensing unit.

2. Cut the pipes a little longer than measured distance.

3. Cut the cable 1.5m longer than the pipe length.

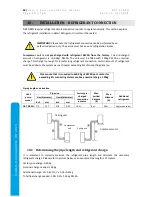

Pressure test / Air purging / Filling the refrigerant

Sometimes bits of air and moisture remains in the refrigerant circuit. If this is not treated, following

symptoms may appear on DRY SIREN:

1.

Pressure in the system rises.

2.

Operating current rises.

3.

Dehumidification efficiency drops.

4.

Blockage of Electronic expansion valve due to frozen moisture resulting in complete failure of

the unit.

5.

Corrosion of refrigerant circuit.

It is thus highly advised to take a leak test after evacuating the complete system. Leak test can be

performed with usual methods using manifold valve and/or soap water. Air purging can be

performed by most commonly applied methods with vacuum pump. This Installation and user

manual elaborates vacuum pump method.

Air purging with vacuum pump / Filling the refrigerant

1.

Preparation

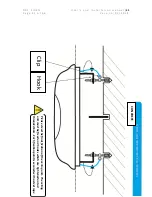

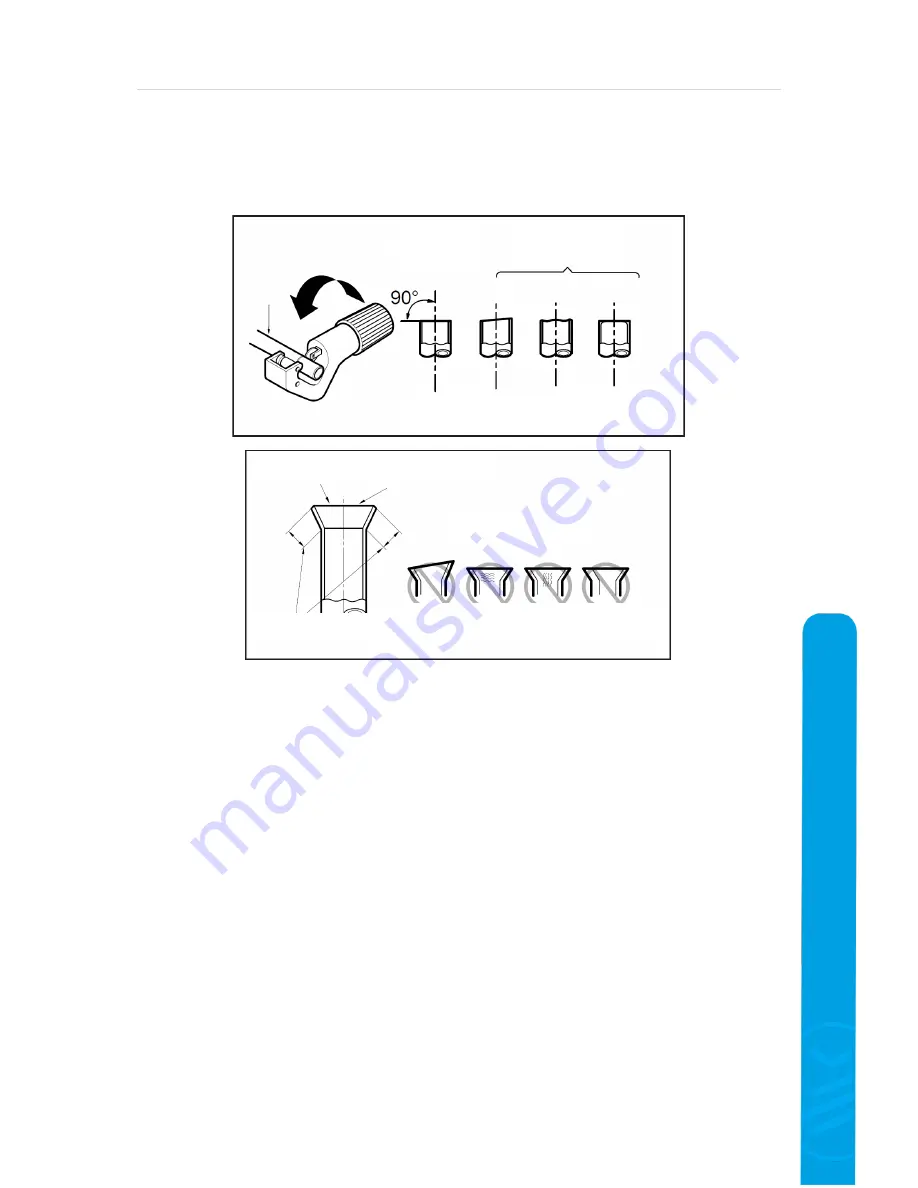

CORRECT

INCORRECT

Even

Slanted

Uneven

Rough

Smooth, shiny without scratches

Same length all around

INCORRECT FLARING

Inclined / Surface damaged / Cracked / Uneven

thickness