Check the condition of the thrust bearing, if the

main shaft has been removed. If the bronze

plates of the bearing are worn out so, that the

depth of the oil grooves is less than 3 mm

(1/8"), the bronze plates must be replaced. The

inspection of thrust bearing must be made at

least once a year. See chapter 9.4.

Check the condition of the protection plates of

the lower frame. Repair or replace if

necessary.

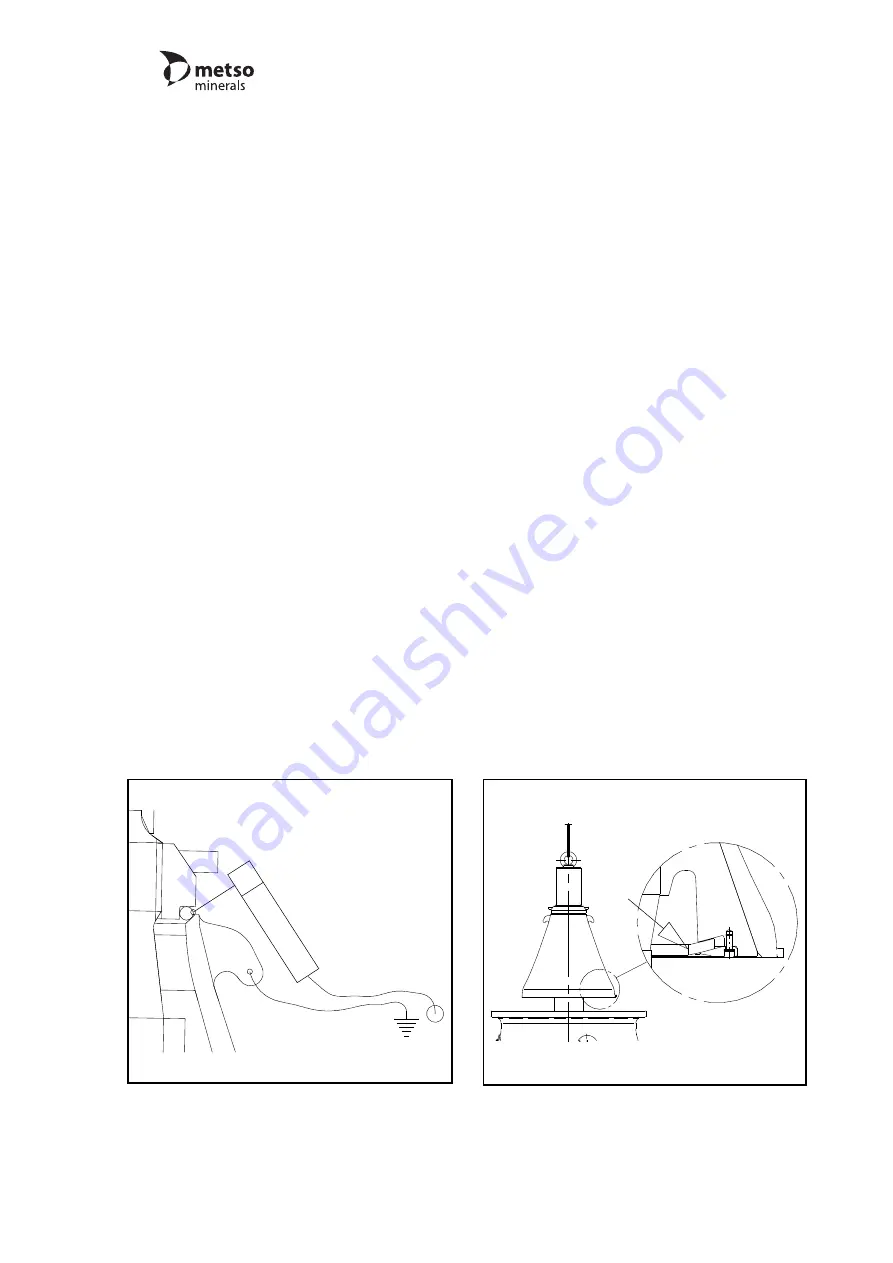

Clean the seating surfaces of a new mantle.

Lift the mantle on the head. Secure, that the

lower edge of the mantle tightly against the

head. No clearance is allowed between the

mantle and head (figure 8.4.3).

Place the new torch ring and nut on the mantle

(figure 8.4.4). The old nut can be used, if it is

still in good condition. Grind smooth the nut

surface which is against the torch ring.

Lubricate the nut thread and screw the nut

down counterclockwise. Tighten it by

hammering. To help the seating, hammer the

mantle to ensure tight seating. Continue

tightening, until the mantle does not clang

when hammered.

After tightening, weld the nut, the torch ring

and the mantle together with six 50 mm (2")

long welds, equally distributed (figure 8.4.4).

Use stainless steel electrode.

If the main shaft has been removed:

— Check, that the intermediate plate of the

thrust bearing has not moved from it’s

location, when lifting the main shaft.

— Before lowering the main shaft, slide the

intermediate plate (steel) on the bearing

plate (bronze) to the eccentric side, to

allow the thrust bearing to settle as well as

possible.

— Lift the main shaft carefully into the

crusher and rotate the shaft a little so that

the thrust plate centers properly. Note, that

the hole of the eccentric bushing is

inclined, Be careful not to damage the

bushing surfaces. Also, be careful not to

damage the dust seal ring, when it slides

around the slip ring (figure 8.4.5).

Figure 8.4.5 Take care of dust seal when

assembling main shaft

Figure 8.4.4 Weld nut, torch ring and

mantle together

Liner replacement

GP200S

12/99

140548

8-7