7 AMI 70 en

7

Type AMI93, 94

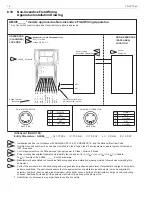

To test sensors, use a 9-32 V DC power supply. No

series load resistor is required. Operate actuator to the

closed position. Apply power across the “FB+” and

“FB-” terminal points. Press and hold “Closed Set” but-

ton until “Closed LED is lit (2 seconds). Release button.

Operate actuator to the open position. Press and hold

“Open Set” button until “Open LED is lit (2 seconds).

Release button. Set points are retained even after

power is removed. A functioning Foundation Fieldbus

network is required to test communications.

WARNING:

Do not apply external power to the output

terminals. this will cause permanent damage to the

unit.

3.2

Fault alerts for AMI96_D

1. The OPEN green LED is lit steady when the valve is

in the open position and the open position sensor is

ON. Input Bit 3 (DI2) will be set to “1”. If the valve is

open and the LED is not lit, perform the sensor set-

ting according to instructions located in Section 3.

2. The CLOSED red LED is lit steady when the valve is

in the closed position and the closed position sensor

is ON. Input Bit 4 (DI3) will be set to “1”. If the valve is

closed and the LED is not lit, perform the sensor set-

ting according to instructions located in Section 3.

3. The SOLENOID POWER yellow LED is lit steady

when Output Bit 3 (DO2) is set to “1” to energize the

solenoid.

4. The BAD SOLENOID COIL red LED will flash at a

2Hz rate if the solenoid pilot valve coil windings are

either open or shorted. The Peripheral Fault Bit will

be set to “1”. Fault indication will clear when solenoid

pilot valve is replaced.

5. The LOW AIR SUPPLY PRESSURE red LED will flash

at a 2Hz rate if the supply pressure drops below 40

psi. Input Bit 1 (DI 0) will be set to “1”. Fault indica-

tion will clear when supply pressure goes back

above 2.8 bar.

6. The STUCK SPOOL/PILOT red LED will flash at a 2Hz

rate if after 5 seconds** of power being applied to

the coil, the internal porting pressure does not rise

above 0.7 bar. Conversely, if after 5 seconds** of

power being removed from the coil and the internal

porting pressure does not drop below 2.1 bar, a

STUCK SPOOL/PILOT fault will be indicated. For

either condition, the Peripheral Fault Bit will be set to

“1”. Fault indication will remain active until internal

porting pressure requirements are met.

7. The STUCK PROCESS VALVE/ACTUATOR red LED

will flash at a 2Hz rate if after 5 seconds** of power

being applied to or removed from the coil, the valve/

actuator does not move by a minimum of 10% of

stroke, provided there is not a STUCK SPOOL/PILOT

or LOW AIR SUPPLY PRESSURE fault already indi-

cated. Input Bit 2 (DI 1) will be set to “1”. A STUCK

PROCESS VALVE/ACTUATOR fault will also be indi-

cated if the valve/actuator doe not reach the com-

manded position within 20 seconds** (Valve open

position when solenoid coil is energized or valve

closed position when solenoid coil is de-energized).

This is also referred to as a “Stroke Time Alarm”.

Input Bit 2 (DI 1) will be set to “1”.

**NOTE:

The Factory default time settings of the Stroke

Time Alarm circuit is 20 seconds for valve Full Stroke

Time and 5 seconds for the STUCK SPOOL/PILOT and

the STUCK PROCESS VALVE/ACTUATOR diagnostic

functions.

The Stroke Time Alarm circuit timing is manually adjust-

able from 1 to 60 seconds.

When manually setting the Full Stroke Time, the sec-

ondary timing used in the STUCK SPOOL/PILOT and

the STUCK PROCESS VALVE/ACTUATOR diagnostic

functions is fixed to one half the time period of the Full

Stroke Time.

(For example: if Full Stroke Time is set to 30 seconds,

the time out for the STUCK SPOOL/PILOT and the

STUCK PROCESS VALVE/ACTUATOR diagnostic func-

tions will be 15 seconds).

See Section 3.3 for Stroke Time Alarm adjustment pro-

cedureure.

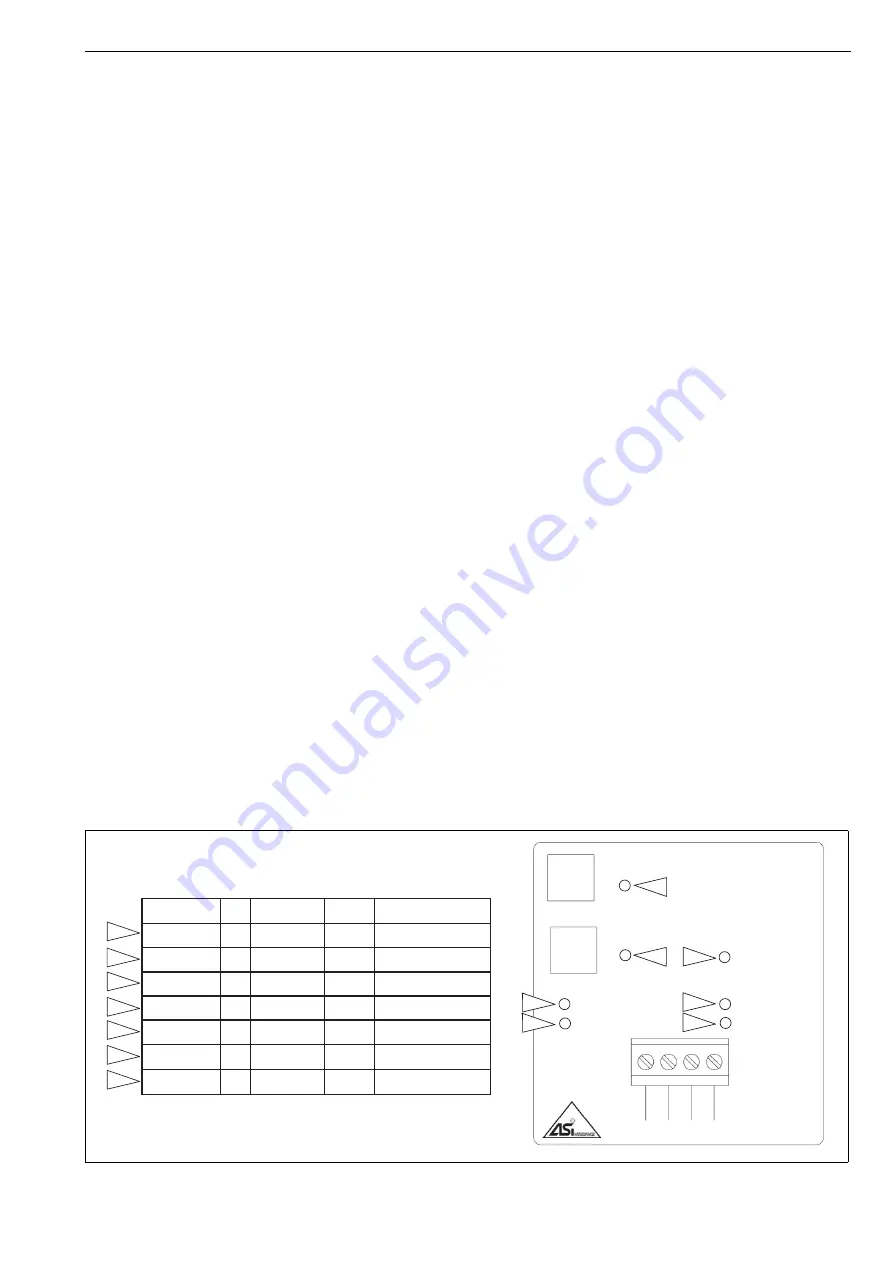

Fig. 5

Diagnostic LED Indications

ASI + (4)

ASI - (3)

SOL OUT+ (2)

SOL OUT- (1)

SET

OPEN

SET

CLOSED

OPEN

CLOSED

SOLENOID POWER

BAD SOLENOID COIL

STUCK SPOOL/PILOT

STUCK PROCESS

VALVE/ACTUATOR

LOW AIR SUPPLY

PRESSURE

Diagnostics: Blinking LED indicates problem

Setup Instructions:

Operate Actuator to Closed

Position and Push SET

CLOSED for 2 seconds.

Operate Actuator to Open

Position and Push SET

OPEN for 2 seconds

3

4

2

1

5

6

7

3

4

5

6

7

1

2

LED

LED

Color

Function

Description

Operational

State

Description

OPEN

Green

Process valve

is open

Normal

Operation

LED will be continuously lit

when process valve is open

CLOSED

Red

Process valve

is closed

Normal

Operation

LED will be continuously lit

when process valve is closed

SOLENOID

POWER

Yellow

Solenoid valve is

energized

Normal

Operation

LED will be continuously lit

when solenoid is energized

BAD SOLENOID

COIL

Red

Solenoid coil is

open or shorted

Fault State LED will flash at a 2Hz rate if

solenoid coil is open or shorted

LOW AIR SUPPLY

PRESSURE

Red

Supply air pressure

is low

Fault State LED will flash at a 2Hz rate if

supply air pressure is <40psi

STUCK SPOOL/

PILOT

Red

Solenoid valve

will not shift

Fault State LED will flash at a 2Hz rate if

solenoid valve does not shift

STUCK PROCESS

VALVE/ACTUATOR

Red

Valve/Actuator

will not turn

Fault State LED will flash at a 2Hz rate if

valve/actuator does not turn