7 AMI 70 en

15

6.9

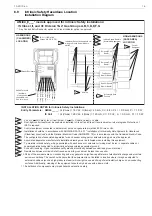

Intrinsic Safety Hazardous Location

Installation Diagram

INSTALLATION NOTES for Intrinsic Safety Installations:

Entity Parameters: AMI44_____:

Ui (Vmax) = 16 Vdc; Ii (Imax) = 25 mA ; Ci = 4.4 nF; Li = 0.0 mH; Pi = 1.0 W

IS Coil :

Ui (Vmax) = 28 Vdc; Ii (Imax) = 120 mA ; Ci = 00 nF; Li = 0.0 mH; Pi = 1.0 W

1. Voc or Vt < Ui (Vmax), Isc or It < Ii (Imax), Ca > Ci + Ccable, La > Li + Lcable.

2. Dust-tight conduit seal must be used when installed in Class II and Class III environments or where Ingress Protection of

IP67 is required.

3. Control equipment connected to barrier must not use or generate more than 250 Vrms or Vdc.

4. Installation should be in accordance with ANSI/ISA RPA12.6.01 "Installation of Intrinsically Safe Systems for Hazardous

(Classified) Locations" and the National Electrical Code (ANSI/NFPA 70) or in accordance with the Canadian Electric Code.

5. The configuration of associated apparatus for each sensor wiring pair or solenoid wiring pair must be approved.

6. Associated apparatus manufacturer's installation drawing must be followed when installing this equipment.

7. To maintain intrinsic safety, wiring associated with each sensor or solenoid coil wiring must be run in separate cables or

separate shields connected to intrinsically safe (associated apparatus) ground.

8. Conduit Grounding - Upon installation verify electrical continuity between conduit and ground terminal.

9. Resistance between Intrinsic Safe Ground and earth ground must be less than one ohm.

10. Parts of the enclosure are non-conducting and may generate an ignition-capable level of electrostatic charge under certain

extreme conditions. The user should ensure that the equipment is not installed in location where it may be subjected to

external conditions (such as high-pressure steam) which might cause a build-up of electrostatic charge on non-conducting

surfaces. Additionally, cleaning of the equipment should only be done with a damp cloth.

11. Substitution of components may impair hazardous location safety.

3

4

2

1

5

6

7

8

9

10

AMI44_E___* models approved for Intrinsic Safety Installations:

IS Class I,II, and III; Division 1&2; Gas Groups A,B,C,D,E,F,G

* Any Conduit Entry/Connector option and Visual Indicator option is approved.

HAZARDOUS

(CLASSIFIED)

LOCATION

NON-HAZARDOUS

(SAFE AREA)

LOCATION

2

4

IS; Cl I,II,III Div 1&2,

Groups A,B,C,D,E,F,G

1

5

6

Intrinsic Safety Barriers

(Associated Apparatus)

3

Control

Equipment

Intrinsically Safe

Ground

9

StoneL Enclosure

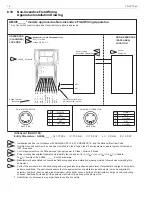

AMI44 Terminal

Identifiers

(If using quick

connectors, see

Pg 3 for pin-out)

10

7

Individual Sensor and solenoid coil

wiring to StoneL Axiom Models

AMI44____

8

Shields

(3) Sol2 Pwr +

(1) Sol1 Pwr +

(2) Sol1 Pwr -

(4) Sol2 Pwr -

(7)

(5) Open +

(6) Open -

(8) Closed -

Bottom Sensor

Namur Barrier

Top Sensor

Namur Barrier

Solenoid Coil

Barrier

Solenoid Coil

Barrier