7 AMI 70 en

5

1.4

CE marking

The limit switch meets the requirements of the Euro-

pean Directives and has been marked according to the

Directive.

1.5

Recycling and disposal

Most limit switch parts can be recycled if sorted

according to material. See the list below for materials.

In addition, separate recycling and disposal instruc-

tions are available from us. A limit switch can also be

returned to us for recycling and disposal against a fee.

1.6

Safety precautions

2

ASSEMBLY AND MOUNTING

Neles Axiom mounting kits are sold separately.

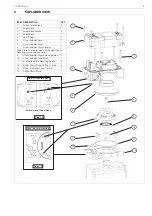

1. Refer to Axiom Assembly Drawing located in Section

4 when performing mounting and assembly proce-

dures.

2. Remove Axiom unit from shipping container. Ensure

all listed items are present.

3. With an M4 allen wrench, loosen the four captive

Axiom Cover Screws (Item# 1), remove cover.

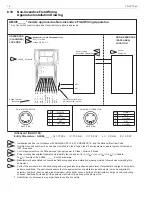

4. Determine if the actuator the Axiom is to be mounted

on is double acting (DA) or spring return (SR). Flip

the Axiom body (Item# 4) over and ensure the DA/SR

Plug (Item# 5) is in the correct position. (See Detail -

A in Section 4). If the DA/SR Plug is in the incorrect

position, gently remove plug with a pair of pliers and

insert into the proper hole.

5. From the mounting kit package, locate the Air Mani-

fold Plate (Item# 14). Place the Air Manifold Plate on

the actuator. Using an M4 allen wrench, fasten down

with the four Air Manifold Mounting Screws (Item#

11). Torque screws to 2.8 - 3.4 Nm.

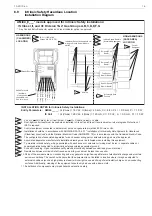

6. Place Visual Indicator Drive Block (Item# 10) into slot

on the actuator shaft. Place Visual Indicator Drum

Coupler (Item# 8) onto the Visual Indicator Drive

Block. Next, place the Visual Indicator Drum (Item#

7) onto the Visual Indicator Drum Coupler. Align the

holes in all three items with the the threaded hole in

the actuator shaft and fasten down with the Visual

Indicator Drum Retaining Screw (Item# 9). Leave

screw loose in order to facilitate indexing of the vis-

ual indicator.

7. With the actuator in the closed position, center the

Visual Indicator Drum until the “OPEN” quadrant is

centered between the “V.I INDEX” markings on the

AIr Manifold Plate. (See Detail - B in Section 4).

Tighten down with the Visual Indicator Drum Retain-

ing Screw 1.7 - 2.3 Nm.

NOTE:

In high cycle or high vibration applications,

blue Loctite® may be used on the Air Manifold

Mounting Screws (Item# 11) and the Visual Indicator

Drum Retaining Screw (Item# 9).

8. Verify Air Manifold Plate Orifice O-rings (Item# 12)

and Visual Indicator Cover O-ring (13) are in place.

9. Place the Visual Indicator Cover (Item# 6) over the

Visual Indicator Drum assembly then set the Axiom

Body (Item# 4) in place. With an M4 allen wrench,

torque the Axiom Body Screws to 2.8 - 3.4 Nm.

10.After all wiring and sensor setting procedures have

been completed, install Axiom Cover and torque

Axiom Cover Screws to 1.7 - 2.3 Nm.

CAUTION:

Do not exceed the permitted values!

Exceeding the permitted values marked on the limit

switch may cause damage to the switch and to equip-

ment attached to the switch and could lead to uncon-

trolled pressure release in the worst case. Damage to

the equipment and personal injury may result.

CAUTION:

To prevent ignition of hazardous atmospheres,

replace cover before energizing the electrical circuits.

Keep cover tightly closed when in operation.

NOTE:

To mount the Axiom requires a mounting kit specific to

the actuator the Axiom is to be mounted to.