13

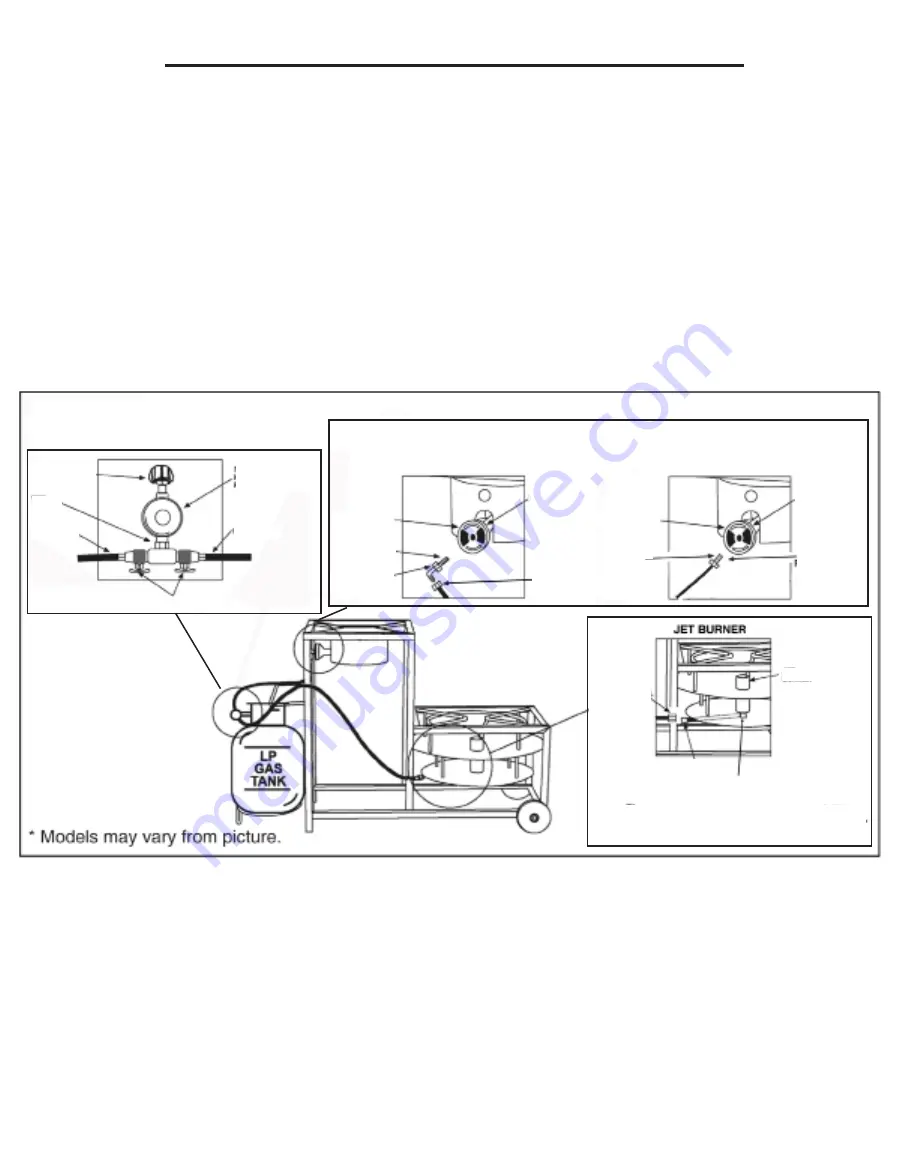

non-AdjustAble regulAtor

wIth mAnuAl VAlVes Assembly

JET PIPE

type 1

connectIon

non-AdjustAble

hIgh pressure

regulAtor

tee

l.p. hose

mAnuAl VAlVes

l.p. hose

cAst burner

(Hose to cast burner assembly will either be made with a 3/8 Female Flare Swivel and Half

Union or a 1/8 Male Pipe Thread depending upon model.)

AIr shutter

orIFIce

hAlF unIon

VenturI tube

3/8 FemAle

FlAre swIVel

3/8 FemAle

FlAre

swIVel

AIr shutter

orIFIce

VenturI tube

1/8 mAle

pIpe threAd

orIFIce cAp

(do not remoVe thIs FIttIng)

the orifice is the drilled hole in the brass cap

which should be pointing up directly into the jet pipe.

brAss AdApter

94/90tKd hose Assembly InstructIons

1. Wrench tighten the 3/8” female flare swivel to the brass adapter. If assembling a hose to a cast

burner, determine if your hose has a 3/8” female flare swivel end or a 1/8” male pipe thread end. If

your cooker has a 3/8” female flare end, wrench tighten it to the pre-installed half union located on

the cast burner. If it has a 1/8” male pipe thread end, tighten the hose fitting into the venturi with a

torque wrench, up to a torque of 95 to 105 lb./in. Alternatively, hand tighten securely and then, using

a wrench, tighten an additional

1-1 1/2 turns.

2. The hose to burner (brass adapter) connections must be tightened and leak tested.

3. Go to the

use and care section

of this manual for further instructions.