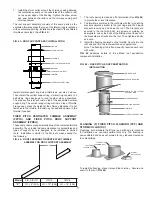

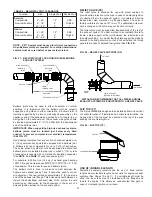

FIG. 16 – METHODS OF STRUCTURAL REINFORCEMENT

FOR ELBOWS

2-45° ELBOWS REINFORCED WITH PLATE SUPPORTS

2-45° ELBOWS REINFORCED WITH WALL SUPPORTS

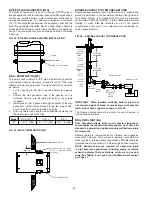

CHIMNEY OFFSETS

Offsets should be avoided except when there is no other way to

route the chimney. When an offset must be used, good design

indicates that the angle used should be the minimum possible (See

FIG. 18

). If the appliance currently burns solid fuel or is capable

of being converted to burn solid fuel, the offset cannot exceed 30

degrees. No more than 2 offsets (4 elbows) may be used.

TABLE 8

indicates minimum center to center offset for two

elbows connected directly to each other.

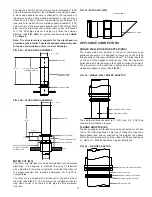

FIG. 17 — MINIMUM ELBOW OFFSETS

(REFER TO TABLE 8)

TABLE 8 - MINIMUM OFFSETS

MINIMUM ELBOW OFFSETS PIC & IPIC-1

PIPE DIA.

“A” - 30° ELBOW

“A” - 45° ELBOW

6” thru 12”

14”

16” thru 24”

26” thru 36”

38” thru 48”

6” (152)

7 3/4” (197)

7 3/4” (197)

8 1/2” (216)

11” (279)

9 7/8” (251)

14 1/8” (359)

14 1/2” (368)

16 5/8” (422)

19 3/4” (503)

MINIMUM ELBOW OFFSETS IPIC-2

PIPE SIZE

“A” - 30° ELBOW

“A” - 45° ELBOW

6” thru 10”

12”

14” thru 22”

24” thru 34”

36” thru 46”

48”

6” (152)

7 3/4” (197)

7 3/4” (197)

8 1/2” (216)

11” (279)

12 3/4” (324)

9 7/8” (251)

14 1/8” (359)

14 1/2” (368)

16 5/8” (422)

19 3/4” (503)

23 3/4” (602)

MINIMUM ELBOW OFFSETS IPIC-4

PIPE SIZE

“A” - 30° ELBOW

“A” - 45° ELBOW

6”

8”

10” thru 18”

20” thru 30”

32” thru 42”

44” thru 48”

6” (152)

7 3/4” (197)

7 3/4” (197)

8 1/2” (216)

11” (279)

12 3/4” (324)

9 7/8” (251)

14 1/8” (359)

14 1/2” (368)

16 5/8” (422)

19 3/4” (503)

23 3/4” (602)

Bracing, above and below the elbows, is needed to avoid

subjecting them to bending moments. In order for bracing to

be effective, it must be rigidly attached to building members or

foundation. The design of the structure used to attach supports

must include the weight of the sloped section and whatever

additional pipe is carried by the support. Additionally, an

expansion joint or bellows joint is needed between the elbows to

relieve thermal expansion stresses.

ANGLE

45° FIXED ELBOW

PLATE SUPPORT

PLATE SUPPORT

ANGLE BRACING

PLATE SUPPORT

ANGLE BRACING

45° FIXED ELBOW

ANGLE

WALL SUPPORT

“A”

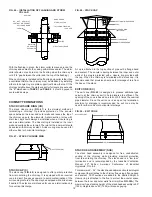

FIG. 18 – SUPPORT FOR CHIMNEY OFFSETS

HALF ANGLE

RING

45° FIXED ELBOW

EXPANSION JOINT

PLATE SUPPORT

MAX. 25 FT. (7620)

(OIL OR SOLID FUEL)

WALL SUPPORT ASSY.

OR PLATE SUPPORT

WALL SUPPORT ASSY.

OR PLATE SUPPORT

30° MAX. FOR OIL OR SOLID FUEL

EXPANSION JOINT

EXPANSION JOINT

30° FIXED ELBOW OR

45° FIXED ELBOW

30° FIXED ELBOW OR

45° FIXED ELBOW

VENTILATED THIMBLE ASSEMBLY

OR ROOF SUPPORT ASSEMBLY

9

used singly or in combination to provide turns of 30, 45, 60,

75, or 90 degrees. For engine or turbine exhaust systems, it

is recommended that 90º turns be accomplished by using two

(2) 45º elbows or a combination of one 45º elbow and one 45º

manifold tee to minimize flow resistance.