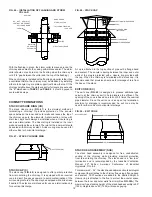

RELIEF VALVE (RV)

The relief valve is intended for use with diesel engines to

provide extra protection to the pipe in case of a delayed ignition

of unburned fuel in the exhaust system. It consists of a spring

loaded disk valve mounted on a flange adapter. The valve is

factory calibrated to open at 27 in. wc. The calibration nuts must

not be changed or the valve may not function correctly.

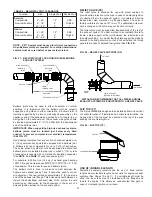

The relief valve must be supported independently of the rest of

the exhaust system. The best method to accomplish this is to

locate a plate support at the joint between the relief valve and

the adjacent fitting. It is crucial that the plate support be properly

secured to building structure so that it can withstand the forces

generated in case of delayed fuel ignition (See

FIG. 58

).

METAL-FAB RECOMMENDS THAT ALL DIESEL ENGINE

EXHAUST SYSTEMS BE EQUIPPED WITH A RELIEF VALVE.

FLIP TOP (FT)

The flip top (

FIG. 59

) is designed to be installed either on a vertical

or horizontal exhaust. If installed on a horizontal termination, the

hinged side of the top must be oriented at the top of the pipe

keeping the counterweight up.

FIG. 58 – RELIEF VALVE SUPPORT (RV)

TO MUFFLER

TO VENT

RELIEF

VALVE

PLATE SUPPORT

(SECURE TO BUIDING)

FIG. 59 – FLIP TOP (FT)

FLIP TOP

CLOSURE RING

21

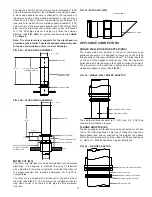

TABLE 9 - BELLOWS JOINT CLEARANCE

Location

Size

Single Wall

Double Wall

Exterior

Combustible

Non-combustible

6” - 48”

6” - 18”

20” - 48”

18”

2”

4”

SEE

TABLE

1

Interior

Combustible

Non-combustible

6” - 48”

6” - 18”

20” - 48”

18”

2”

4”

SEE

TABLE

1

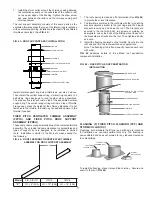

FIG. 57 – BELLOWS JOINT LOCATION IN DIESEL ENGINE

EXHAUST SYSTEM

Bellows joints may be used in either horizontal or vertical

positions. It is imperative that the bellows joint be properly

supported and guided in either orientation. A bellows joint is

typically supported by a plate or wall support assembly on the

appliance end of the bellows and guided by a full angle ring or

wall guide on the exhaust end. The exhaust side guide should

be located approximately 6”-12” (152-305) from the downstream

end of the bellows joint.

IMPORTANT: When supporting high rise exhaust systems,

bellows joints must be located just below every fixed

support to prevent compression at ambient temperatures

(See FIG. 57).

Good design indicates that any section of exhaust piping over

4’ (1.2m) between fixed points be equipped with a bellows joint.

A bellows joint can compensate for up to 3” (76) of expansion.

The entire exhaust system should be examined to assure that

bellows joints are installed in pipe runs in which 3” (76) or less

of expansion is expected. For a method of calculating expansion

(See

NOTE 3 on PAGE 11

under expansion joints).

For example, a 60-foot run (18.3m) of exhaust pipe handling

1000º F flue gas would produce 60ft/100 X 1000ºF/100 = 6” (152)

of expansion. This run would require 2 bellows joints.

The bellows joint is lined to minimize contact between the

bellows and exhaust gases. Thus, it cannot be used to correct

mis-alignment. The liner extends approximately 2” (51) past one

end of the bellows joint flange. This extension should always be

toward the downstream (exhaust) side of the system to avoid

becoming an obstruction for the shockwave in the event of a

delayed ignition incident in the exhaust system.

3” (76) EXPANSION

MAXIMUM

HALF ANGLE

LINER

TOWARD VENT

APPLIANCE OUTLET

BELLOWS

JOINT

BELLOWS

JOINT

PLATE SUPPORT

PLATE SUPPORT

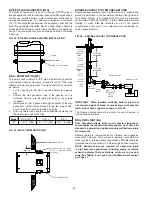

USE OF VARIABLE LENGTH

Metal-Fab generally recommends the use of fixed custom

lengths where standard lengths do not work for engine exhaust

systems (See Pages 10 and 11). If a variable length must be

used, the inner tube must be installed with the flanged end

toward the engine. This allows an unobstructed flow path in

case of a delayed ignition occurrence.

NOTE: P071 Sealant must be used for all joint connections

when Bellows Joints are required. For exterior installations,

sealant must be cured before exposure to moisture.