NOTES:

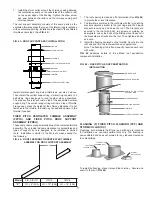

1. It is recommended that the pipe adjacent to the variable

length is supported or guided to prevent sagging.

2. If a variable length must be installed adjacent to a tee,

elbow, wye or other fitting where tube can interfere with

flow, the unflanged end of the tube should be away from

the fitting and fitted into a pipe length in the manner

described in the installation procedure under FIG. 23.

3. A variable length may be installed with a flange to flange

length between 4” and 26” (102 and 660) inclusive.

4. If inner tube is too long, it may be cut to length. Tube

must be a minimum of 4” (102) longer than flange to

flange length. Prior to installation of cut pipe, remove all

burrs to ensure that interference does not occur.

5. Note that the variable length will not support any weight

in the vertical position.

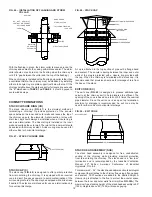

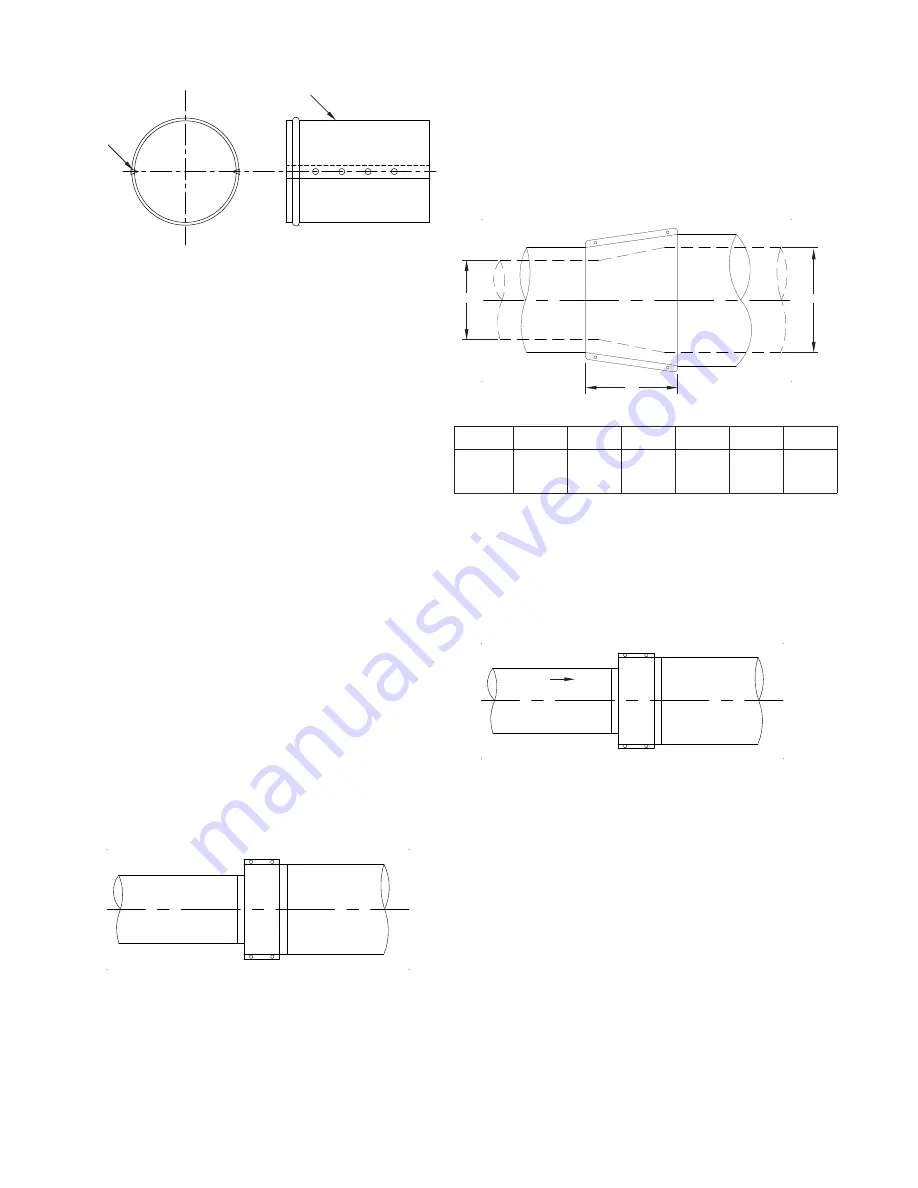

STEP INCREASER (SI) AND TAPERED INCREASER (TI)

Frequently, a diameter change is required in a chimney

installation. To accomplish such a size change, a step increaser

or tapered increaser may be used. These parts are usually used

to provide an increase of size, as the name implies. However,

they may be used to reduce the size of a run. Extreme caution

should be exercised when reducing the size of a chimney. The

resultant pressure drop may cause the chimney to mis-function

and cause spillage of flue gases into the mechanical room.

The step increaser should be used when the length of run

available for the size change is restricted. The installed length of

a step increaser is 2” (51) (See

FIG. 25

). The step increaser is a

non-structural part and must not be subjected to loading in either

the axial or lateral directions.

FIG. 24 – VARIABLE LENGTH CASING ASSEMBLY

Note: For IPIC, wrap increaser with insulation before

attaching outer casing. Care must be taken to completely fill

all gaps with insulation.

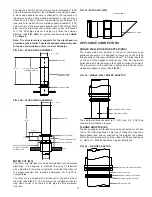

When sufficient length is available, use of a tapered increaser

is recommended, since it causes a considerably less pressure

drop than an equivalent step increaser. The tapered increaser

uses 5 inches of length per incremental diameter change. The

maximum length for a tapered increaser is 30” (762) or 6 pipe

sizes. A tapered increaser is considered to have the same load

strength as straight pipe (See

FIG. 26

).

STEPS

1

2

3

4

5

6

“C” =

5”

(127)

10”

(254)

15”

(381)

20”

(508)

25”

(635)

30”

(762)

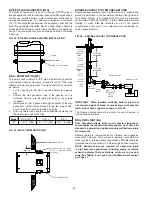

TRANSITION BAND (TB)

The transition band provides the necessary increase or decrease

in casing diameter when change in insulation thickness occurs

(

FIG. 27

).

FIG. 26 - TAPERED INCREASER (TI)

FIG. 27 - TRANSITION BAND (TB)

Note: Wrap pipe joint with insulation before attaching outer

casing. Care must be taken to completely fill all gaps with

insulation.

HALF JACKET

SCREWS

(INCLUDED)

FIG. 25 - STEP INCREASER (SI)

INSTALLS AT 2” (51)

“A”

“B”

“C”

AIR FLOW

12