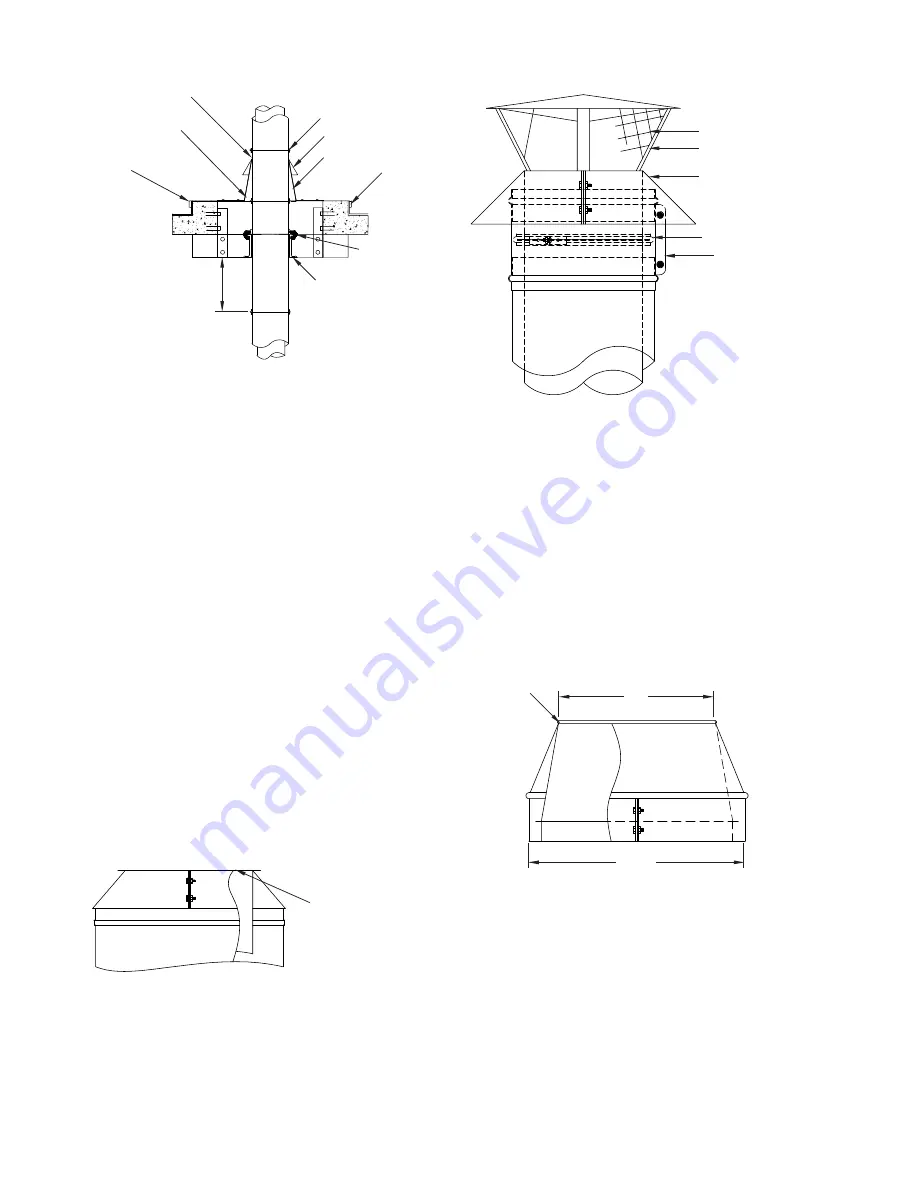

CHIMNEY TERMINATIONS

STACK CLOSURE RING (CR)

The stack closure ring (

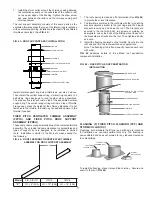

FIG. 47

) is the simplest method of

terminating a chimney. It provides protection of the annular

space between the inner and outer walls and leaves the top of

the chimney open to the elements. A drain section (or tee with

drain tee cap) should always be installed when a closure ring is

used as a termination. The closure ring is installed on the inner

wall and overlaps the outer wall. The joint at the inner wall should

be sealed with chimney sealant. A closure ring may be used for

either vertical or horizontal discharge.

FIG. 47 – STACK CLOSURE RING

STACK CAP (C)

The stack cap (

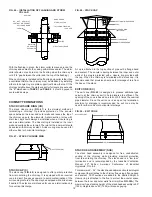

FIG. 48

) is designed to offer partial protection

from rain entering the chimney. It is equipped with an inverted

cone to divert flue gases upward to avoid contamination of the

surrounding roof area. The cap may be equipped with a birdscreen

if desired. The stack cap is intended for use as a termination only

for a vertical discharge.

A cap is attached to the top section of pipe with a flange band

and sealant. The annular opening between the inner and outer

walls of the pipe is protected with a closure ring provided with

the cap. When the chimney is terminated with a stack cap, it is

recommended that provisions be made for drainage of rain from

the base of the stack.

EXIT CONE (EC)

The exit cone (

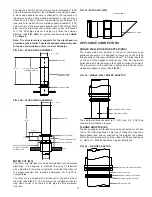

FIG. 49

) is designed to produce additional gas

velocity at the chimney exit to help disperse the effluent. The

opening of the cone is based on a ratio of 0.8 times the nominal

pipe diameter. Since the exit cone is an open top termination,

provision for drainage is recommended. An exit cone may be

used for either vertical or horizontal discharge.

FIG. 49 – EXIT CONE

STACK HEAD ASSEMBLY (SHA)

The stack head assembly is designed for free, unobstructed

venting of the chimney while providing maximal protection

from rain entering the chimney. The stack head is a “low loss”

termination and is recommended by the Industrial Ventilation

Manual, 20

th

Edition, American Conference of Industrial

Hygienists, FIG. 8-6.

For diameters 6” – 24”, the stack head adapter section is an integral

component that attaches to the chimney flue using a flange band

and sealant. PSW sections are added to the desired height. A

closure ring is attached to the flue to protect the annular space

between the inner and outer walls from rain (See

FIG. 50A

). The

maximum free standing height of the stack head assembly is 60”

(1524). Heights above 60” (1524) will require guying.

FIG. 48 - STACK CAP

APPLY SEALANT

OPTIONAL BIRD SCREEN

CAP

CLOSURE RING

(INCLUDED)

FLANGE BAND

CLOSURE BAND

APPLY SEALANT

0.8 D

PIPE I.D.

18

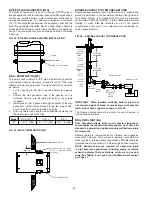

FIG. 46 – INSTALLATION OF FLASHING AND STORM

COLLAR

With the flashing in place, the storm collar is placed around the

chimney and sealed to the casing with silicone sealer. The storm

collar should not quite rest on the flashing when the chimney is

cold (1/4” gap between the collar and the top of the flashing).

When a chimney is installed with a flashing and collar rather than

a ventilated thimble, the chimney must be stabilized by installing

either a full angle ring or a plate support just below the roof. If the

chimney height above the plate support or full angle ring exceeds

the “B” dimension in

TABLE 7 on PAGE 5

, it must be guyed to

avoid wind damage.

FLANGE BAND

STORM COLLAR

TALL CONE FLASHING

16 GA. PAN

PLATE

STRUCTURAL FRAME

MAINTAIN

ADEQUATE

EXPANSION

CURB

DO NOT RESTRICT

VERTICAL MOVEMENT

OF FLANGE BAND

SEALANT