CHIMNEY ENVIRONMENT

It is suggested that a chimney being installed in a corrosive

atmosphere be constructed of Type 316 stainless steel.

Type 316 stainless is resistant to corrosion and will add to

the life expectancy of the installation. Chemicals containing

halogen compounds should not be allowed to contaminate the

combustion air supplied to the heating equipment. Storage or

use of chemicals containing chlorine or chlorides in the vicinity

of equipment, or the presence of these compounds in the fuel,

or combustion air supply may lead to early deterioration of the

chimney.

Chemicals which may cause attack on chimney materials include

(but are not limited to):

•

chlorinated or halogenated dry cleaning solutions,

•

fluorocarbon refrigerants,

•

hydrochloric (muriatic), sulfuric or other acids,

•

fluorocarbon aerosol propellants,

•

vinyl plastics (when burned),

•

chlorine bleach and cleaning solutions,

•

titanium tetrachloride, or

•

plating or etching baths or solutions.

Any of these chemicals passing through the combustion process

produce acids which can corrode the heating equipment and the

chimney.

If corrosion is found, an immediate investigation should be

undertaken of the entire area. Any corrosive materials should

be removed to avoid future contamination. A contaminate-free

atmosphere for combustion and ventilation air must be obtained.

It may be necessary to pressurize the equipment room with its

own air supply. Any surface discoloration should be carefully

studied as it may be caused by contaminates in the fuel, or

corrosion of mild steel components of the chimney system, the

breeching system, or the equipment being vented and may be

indicative of deterioration of other components of the heating

system.

Whenever the local atmosphere is high in pollutants, constantly

or intermittently, it is recommended that the chimney components

be of all stainless steel construction. When chimney is exposed

to the elements, it is recommended that the outer wall be

either painted with one base coat and one finish coat of a heat

resistant primer and paint, or that the outer wall be constructed

of stainless steel.

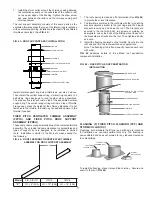

TERMINATION HEIGHT REQUIREMENTS

Model PIC/IPIC chimney is to terminate a minimum of 3’ (914)

above the highest point where it passes thru a roof of a building

and a minimum of 2’ (610) higher than any portion of a building

within a horizontal distance of 10’ (3.05m) (See

FIG. 1

).

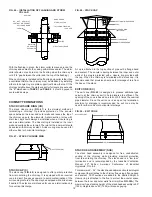

CLEARANCES – BOILERS AND ENGINES

CAUTION– DO NOT ENCLOSE IN A CHASE OR PASSAGEWAY

OF COMBUSTIBLE MATERIAL

For appliances operating with continuous exhaust temperatures

up to 1400º F, where the chimney is installed in an open room

or fully ventilated area on the same story as the appliance to

which it is connected, Model PIC/IPIC Chimney shall be installed

at a minimum of the clearance to combustibles as indicated in

TABLE 1

.

Except for installation in one or two family dwellings, a factory-

built chimney that extends through any zone above that on which

the connected appliance is located is to be provided with an

enclosure having a fire resistance rating equal to or greater than

that of the floor or roof assemblies through which it passes.

Metal-Fab Model PIC/IPIC Chimney can penetrate a combustible

roof by utilizing the Roof Support Assembly (RSA) or Ventilated

Thimble Assembly (VTA). All other parts are for attachment to

non-combustible construction (i.e., floor guides, wall guides,

plate or wall support assemblies).

TABLE 1 - PIC/IPIC INSTALLATION CLEARANCES

Operating Temperature

1000°F Continuous

(538°C)

1400°F Intermittent

(760°C)

1400°F Continuous

(760°C)

1800°F Intermittent

(982°C)

Insulation

Thickness

PIC

IPIC-1 IPIC-2

IPIC-4

PIC

IPIC-1

IPIC-2

IPIC-4

Exterior Wood Frame or Combustible Wall

Diameter: 6”

8 - 16”

18”

20”

22”

24 - 26”

28 - 32”

34”

36 - 40”

42 - 48”

4” (102)

4” (102)

5” (127)

6” (152)

6” (152)

6” (152)

6” (152)

6” (152)

6” (152)

6” (152)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

4” (102)

4” (102)

6” (152)

8” (204)

9” (229)

10” (254)

10” (254)

10” (254)

10” (254)

10” (254)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

Exterior Non-Combustible

Diameter: 6”

8 - 18”

20 - 42”

44 - 48”

2” (51)

2” (51)

4” (102)

4” (102)

1” (25)

2” (51)

3” (76)

4” (102)

1” (25)

1” (25)

1” (25)

1” (25)

2” (51)

2” (51)

4” (102)

4” (102)

1” (25)

2” (51)

3” (76)

4” (102)

1” (25)

1” (25)

1” (25)

1” (25)

Interior Wood or Other Combustibles

Diameter: 6”

8 - 16”

18”

20”

22”

24”

26”

28 - 32”

34”

36 - 40”

42 - 48”

4” (102)

4” (102)

5” (127)

6” (152)

7” (178)

8” (204)

9” (229)

10” (254)

10” (254)

10” (254)

10” (254)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

3” (76)

3” (76)

4” (102)

4” (102)

6” (152)

8” (204)

9” (229)

10” (254)

10” (254)

10” (254)

10” (254)

10” (254)

10” (254)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

3” (76)

3” (76)

Fully Enclosed Combustibles (UL103-HT)

Diameter: 6”-14”

N/A

N/A

2” (51)

N/A

N/A

N/A

Fire Rated or

Non-Combustible

Chase

As necessary for installation and access, refer to NFPA 211.

Note: The above figures represent air space, in inches, from

outer surface to surroundings.

NOTES:

1. False ceilings are a potential hazard and require

firestopping. Chimneys passing through areas between

ceiling and roof must be installed in fire-rated

enclosures in accordance with local building codes.

2. Decorative shrouds at the termination of a factory built

chimney shall not be permitted per NFPA 211.

2’ (610)

LESS THAN

10’ (3048)

MORE THAN 10’ (3048)

3’ MIN. (914)

STRUCTURE

CHIMNEY OR VENT

3

FIG. 1 - TERMINATION HEIGHT REQUIREMENTS