and

SQA-V

Service Manual Dec_2019

31

8.

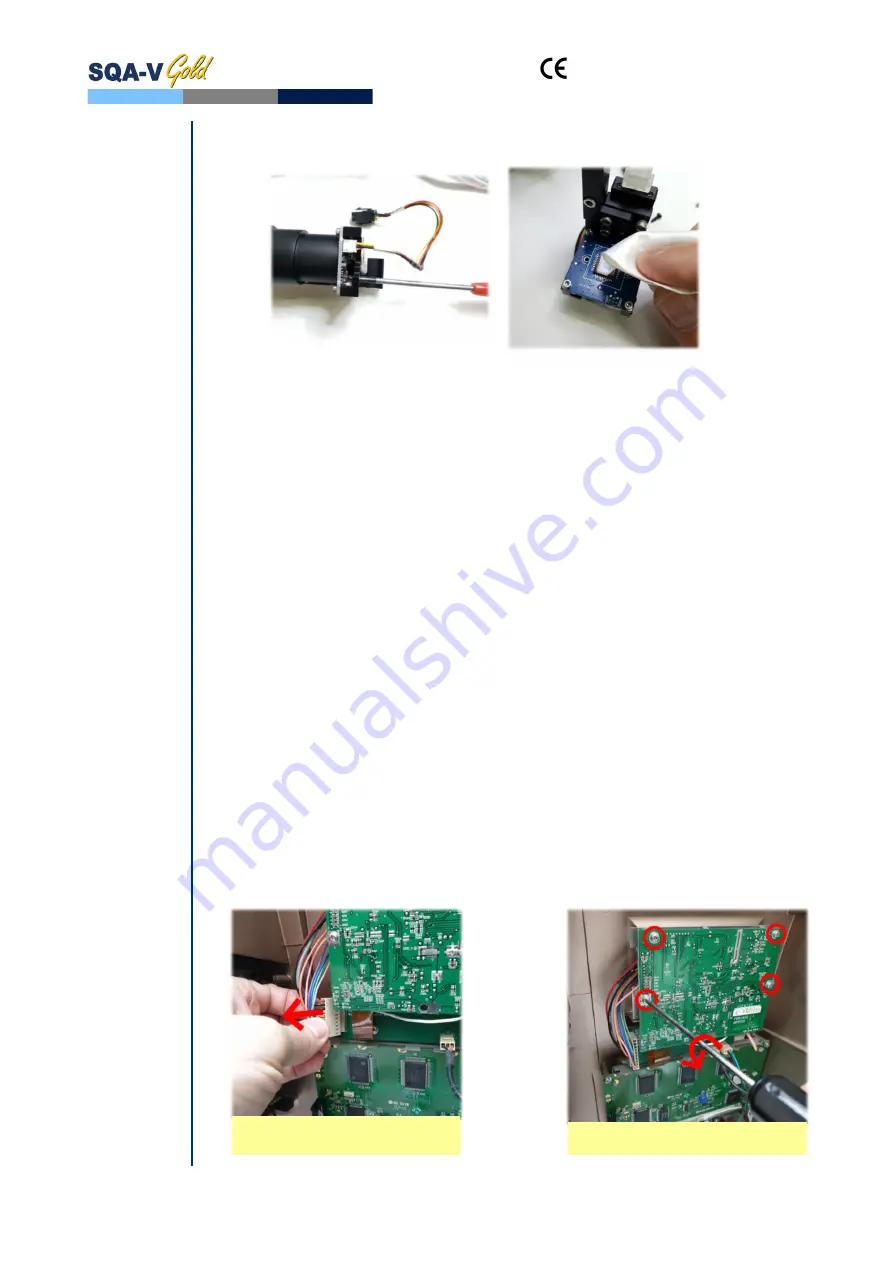

Remove the dust sleeve by unscrewing 2 Phillips screws (fig. 10).

9.

Gently clean the CCD using lint free microfiber cloth (fig. 11).

10.

Attach the dust sleeve back to the CCD board and fasten 2 Phillips screws through

designated holes in CCD tray

11.

Carefully align the false track tool with the metal guide rail and gently push the CCD

tray back over the guide rail.

12.

Re-install the black stopper to the bench and fasten the screws.

13.

Re-connect the internal and external video cables.

14.

Assemble the lid on the base of visualization system and fasten the screws.

15.

Assemble the DC motor, and make sure the cogwheel teeth coincide with the teeth of

the white plastic rack.

16.

Re-attach the visualization system back to the front panel.

Instructions

for all range

of SQA-V’s

serial

numbers

17.

Replacing the CCD camera (no image on both SQA-V and V-sperm)

1.

Follow the instructions for CCD cleaning, but this time do not remove the dust sleeve.

2.

Using a Phillips screwdriver remove the four screws holding the camera PCB.

3.

Replace the defective CCD camera with a new one.

4.

Fasten the four screws holding the CCD camera.

5.

Follow the rest of instructions to finish the assembling of the visualisation system and

re-attach it to the front panel.

Video screen

18.

Video screen (Part# LCD-0010)

ISSUE:

The image on the Video Screen is wavy

Note:

This repair can

only be

performed for

SQA-V of SN

1505 and

above. For

systems with

different serial

numbers,

please contact

MES support

services.

1.

Open the SQA-V device

2.

Disconnect the video screen cable from Control board

3.

Using a Phillips screwdriver, remove the screws holding the PCB of the video screen

4.

Remove the hollow spacers holding the Video screen

5.

Replace the defective video screen with new one

6.

Re-assemble the spacers

7.

Using a Phillips screwdriver, secure the PCB of the video screen with the screws

8.

Connect the video cable of the new video screen

9.

Close the SQA-V

Fig. 10

Fig. 11

Remove the screws

Disconnect the Video screen

cable