Page 22

Check Bearing End Play

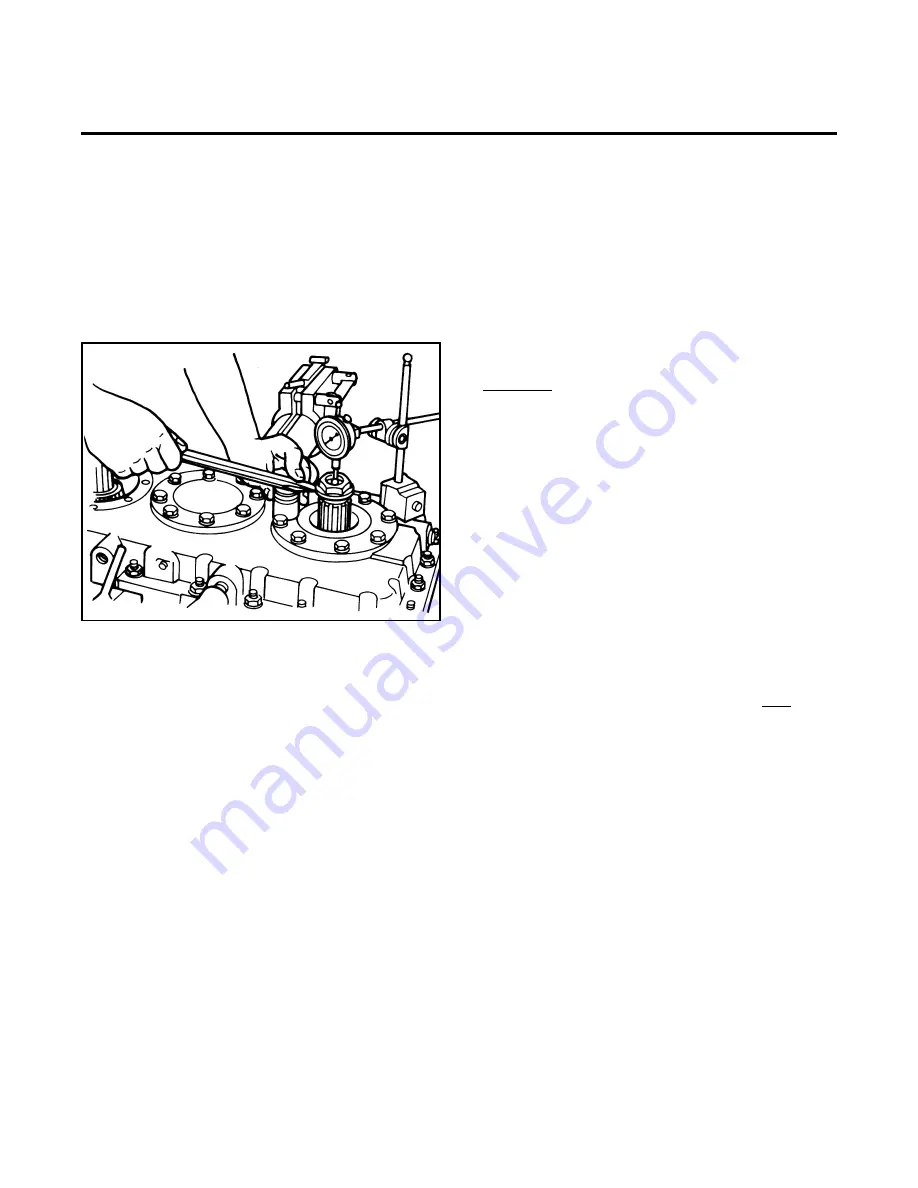

1. Install the yoke nut on the input shaft finger tight.

2. Set a small steel ball in the hole on the end of the

input shaft.

3. Check the end play with a dial indicator mounted

against the ball on the shaft. Figure 30.

NOTE:

It is critical that the bearings be completely seated

in both directions.

a. Seat the lower bearings by using the weight of

the gear plus a rotational and shaking motion.

Proper seating of the lower bearings is indicated

when movement of the dial indicator ceases. At

this point, zero the dial indicator.

b. Using the same rotational and shaking motion,

apply upward lift sufficient to seat the upper

bearing. Proper seating of the upper bearing is

indicated when the dial indicator ceases to

register upward movement.

NOTE:

The movement indicated by the dial indicator is the

preliminary end play that exists with the initial shim

stack.

c. Subtract the appropriate shim quantity and

thickness to close the end plays to within the

specified limits.

Example:

0.058 in. (1.473 mm) Preliminary end play

-0.003 in. (0.076 mm) Nominal desired end play

=0.055 in. (1.39 mm) Shim stack to be removed

4. The end play must be between 0.001 - 0.005 inch

(0.025 - 0.127 mm). Add shims to increase end play

or remove shims to decrease end play.

5. To check the end play of the rear output shaft, the

transfer case must be rotated so that the rear output

is on top.

6. Install the snap ring in the end of the output shaft.

7. Check the end play with a dial indicator mounted

against the end of the shaft. Take the reading while

you pry up against the snap ring and rotate the shaft

in both directions.

8. The end play must be between 0.001 - 0.005 inch

(0.025 - 0.127 mm). Add shims under the front output

bearing cage to increase end play or remove shims

to decrease end play.

Figure 30

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]