gizing a 220 volt heater.

This causes the normally

closed bi-metallic relay switch of this control to open

after a delay of approximately 90 seconds or less,

stopping the compressor and closing the liquid line

solenoid valve. The time delay prevents nuisance trip

out on momentary low suction pressure and permits the

operation of the system on a “pumpdown cycle”.

The control must be checked while the system is

operating. To check the control, install a volt meter

or 220 volt light across terminal T1 and T2 of the low

pressure freeze control. There should be a voltage

indication or the test light will glow indicating the

contacts are opened. Throw the pumpdown switch to

the manual position and check the pressure at which

the test light goes out or the volt meter goes to zero.

In actual operation, the compressor wi II shut down and

the safety light will go out. The control can be man-

ually reset in about 2 minutes.

Thermostat - The thermostots supplied on all pack-

aged chillers are factory calibrated for use in the re-

turn water line to the cooler inlet. The thermostat

bulb is installed in a well in the return water line in

order to be more stable under temperature changes due

to load conditions. The return water does not change

temperature as rapidly as the outlet because of the

“fly whee I effect” of the total water system. This re-

sults in stable control of the outlet water temperature.

Normally the thermostat requires no adjustment in the

field other than the dial setting for the required con-

trol point.The control is preset at the factory to main-

tain a 44F average leaving water temperature through-

out the loading and unloading sequence of the unit,

based on a full load cooling range of 10F. It should

be realized, however, that there will be a fluctuation

in the leaving,water temperature as the unit cycles,

unloads and loads.

On a two stage thermostat, the dial setting indi-

cates the average leaving water temperature that the

control will maintain.At a 44F setting, the high stage

should actuate at approximately 51F return water and

41F leaving based on 10F. cooling range. The low

stage will open at 46F return or 41 F leaving (5F TD

or 50% capacity). As the water warms up, the low

stage should cut in at approximately 49F which is the

inlet and outlet temperature with the unit off and the

high stage should operate at 54F return or 49F leaving.

These settings may be checked by operating the

unit and slowly regulating the load from full to mini-

mum and return. It may then be necessary to adjust the

dial and/or differential between switches to obtain

these values.

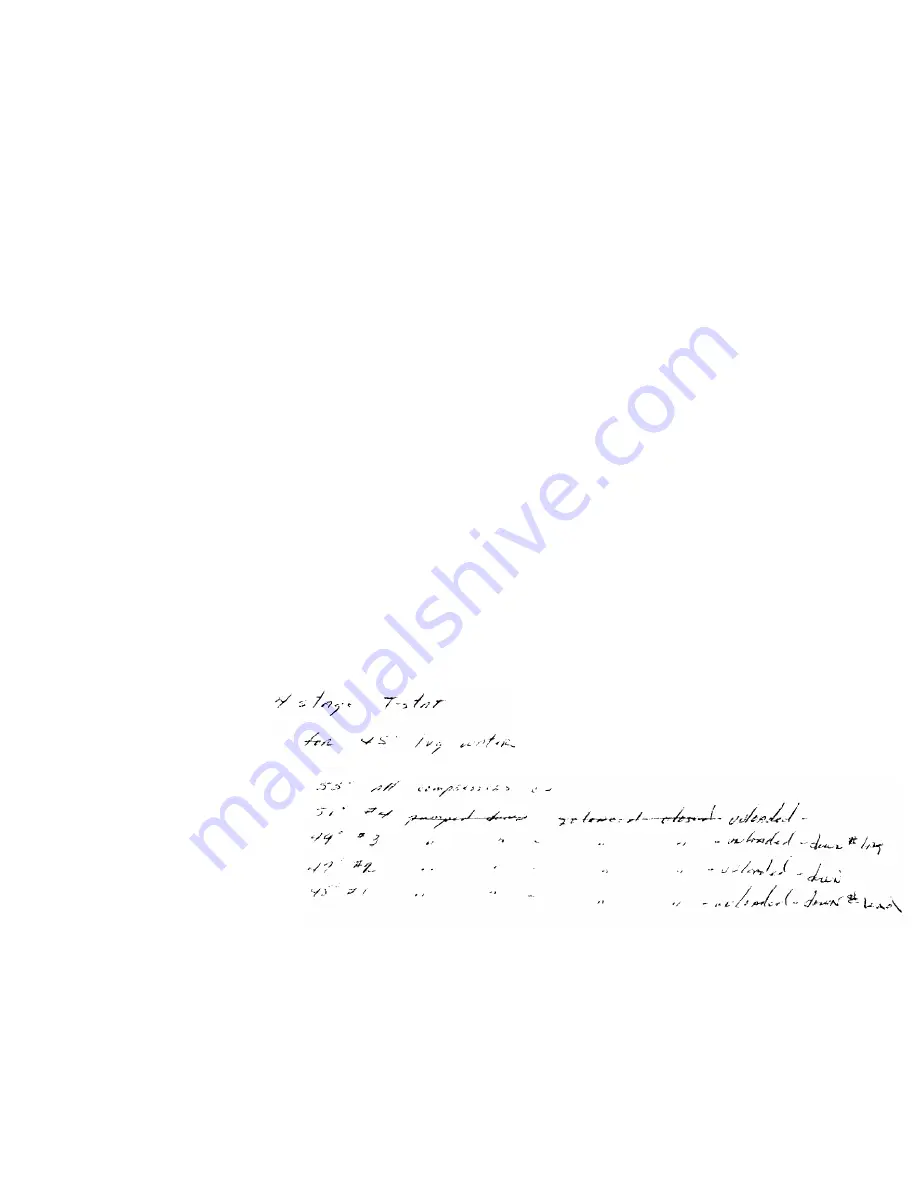

On a four stage thermostat, the dial setting indi-

cates the cut out point of the low stage switch which

represents the average leaving water temperature de-

sired. The high stage or #4 switch should be actuated

at approximately 51F return water temperature, #3 at

49F, #2 at 47F and #1 at 45F which is the dial setting.

The cut in point will be approximately 2F higher than

the cut out on each switch.

These settings may be checked by operating the

unit and slowly reducing the load. The four stage

thermostat has a fixed switch differential and fixed

differential between switches. DO NOT make any ad-

justments other than the dial as this is a preset pre-

cision control.

CAUTION: Response time on thermostat is slow, con-

sequently, approximately 5 minutes must be allowed

for bulb response (after attaining system steady-state

operotion) before any or each adjustment to thermo-

stat is made.

Page 25