FM ANT

Either a 300 ohm balanced or 75 ohm unbalanced

antenna can be connected to the MR-65. The 300 ohm

input is balanced and connected internally through a

special balun designed by Mclntosh. The 75 ohm un-

balanced antenna connection is between one side of

the 300 ohm input and ground.

TO TV SET

A VHF television antenna may be used for FM recep-

tion. An internal switch on the MODE SELECTOR con-

nects the MR-65 between a TV antenna and a TV receiver.

With the MODE SELECTOR turned to any operating posi-

tion the VHF-TV antenna is disconnected from the TV set

and connected to the MR-65. When the MR-65 is turned

off, by rotating the MODE SELECTOR to the POWER OFF

position, the antenna is switched directly to the TV

receiver.

FUSE

The MR-65 uses a 1 ampere "Slo Blo" type fuse. The

Auxiliary AC outlet is not fused.

AC OUTLET

A maximum of 350 watts may be connected to the

AC outlet. The outlet is not fused. The MODE SELECTOR

on the front panel controls the power to this receptacle

and turns the power off in the POWER OFF position.

LAMPS

The dial light brightness is controlled by this switch.

Simply switch to HI or LO brightness to suit your in-

stallation.

INSTALLATION INSTRUCTIONS

The MR-65 can be installed in conventional cabinets,

custom built-ins or professional equipment racks. If the

MR-65 is to be placed on a bookshelf or table-top, the

Mclntosh Model L-66 cabinet may be used to enclose the

chassis. The MR-65 is installed from the front of the

cabinet. . . not from the rear. The minimum thickness of

wood panels used to mount the MR-65 should be ¼" . . .

and panels up to 1" thick may be used.

A shelf is required to support the rear of the chassis

when the front panel is made of wood. It is important to

make a suitable cutout in the shelf for ventilation. When

mounted on a metal rack panel, a shelf is not needed.

The space in which the MR-65 will be installed should

be at least 13¾" behind the front panel to allow about

1½" for connectors. Allow at least 16½" for width and

5½" for height so there will be sufficient space for cir-

culation of air. These are inside dimensions.

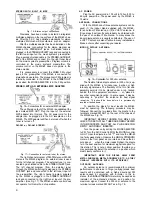

Fig. 10—Positions "A" to "C" showing the location of

the vertical center line; how the measuring tool

(mounting strip) is used to locate the horizontal

center tine, and to measure off the two points to

the right and left of the vertical center line.

MAKING THE FRONT PANEL CUTOUT

The panel is cut out using the "FRONT PANEL CUT-

OUT TEMPLATE." To position the template on the front

of the panel, it is necessary to make two locating holes

from the back (inside) of the panel using one of the

mounting strips (½" by 3½") as a measuring tool. Pro-

ceed as follows:

Measure the exact center of the proposed cut out

area and scribe a vertical center line from the top of the

panel down to the top surface of the shelf. See position

"A" in Fig. 11. Draw a horizontal line 3½" above the shelf

using one of the mounting strips as a measuring tool.

See position " B " in Fig. 11. Now—place a mounting strip

along the horizontal line to the left of the vertical center

line and mark a point 3½" left from the vertical center

line. Repeat this procedure and mark a point 3½" right

from the vertical center line. These points should now be

3½" up from the top of the shelf and 7" apart, one 3½" to

the left and one 3½" to the right of the vertical center

line. See position "C" in Fig. 11. Drill a

3

/

16

" hole at each

point—take care to hold the drill perpendicular to the front

panel so that the hole will be located accurately on the

front of the panel.

Position the template on the front of the panel using

the two locating holes to line it up correctly. Scribe the

rectangular opening on the front panel and mark the

position of the six mounting holes. Drill the six

3

/

16

"

mounting holes before cutting the panel opening. Then

cut out the opening. It is important that the cutout be

just within the lines.

MAKING THE SHELF CUTOUTS

If the installation uses a shelf, it must be cut out to

provide ventilation below the chassis. To make the cut-

out, use the "SHELF CUTOUT TEMPLATE." Locate the

center of the shelf and scribe a line from front to back.

The template is marked for panel thicknesses from ¼" to

1". Fold on the line that corresponds to the thickness of

the panel. Place it on the shelf so that it butts against the

inside of the panel. Match the center line mark on the

template to the scribed center line on the shelf. Mark the

position of the four holes and scribe the square ventila-

tion opening. Drill the four ¼" holes and cut out the

ventilation opening.

INSTALLING THE MR-65

Remove the four screws holding the MR-65 to the

shipping pallet (save these screws, you will need them if

your cabinet has a ¼" or

3

/

8

" shelf.) Remove the four

plastic feet.

In the mounting hardware package are four 6-32

flathead screws and eight 6-32 roundhead screws. Two

of the flathead screws of the proper length are used to

attach the mounting strips to the cabinet. Four of the

roundhead screws of the proper length are used to

attach the MR-65 to the cabinet and mounting strips.

The 6-32 x ½" screws are to be used with panels under

3

/

8

" in thickness. The 6-32 x ¼" screws are to be used with

panels ½" to 1" in thickness.

4