25

◼

Spray Inspection

(1) Opening the Spray Cock and Checking the

Spray Condition

[1] Inspect the nozzle for clogging due to dust, etc.

[2] Check the open/close condition of the main spray

cock and each spray cock (left nozzle, center

nozzle and right nozzle).

⚫

Long hours of use causes the nozzle plate to wear

and discharge flow rate to increase. When this

happens, replace the nozzle plate.

⚫

Types and quantities of standard factory-set nozzles

[Other than J or L type]

Left boom

Ceramic cone

nozzle

(

1.6)

Kirinashi

nozzle

N-KA-8R

23 pcs

Center boom

7 pcs

Right boom

23 pcs

Total

53 pcs

⚫

Table of nozzle discharge flow rates (per nozzle)

Ceramic cone nozzle

(L/min)

1.0 MPa

1.5 MPa

2.0 MPa

1.0

0.53

0.66

0.77

1.1

0.60

0.73

0.85

1.2

0.66

0.82

0.96

1.3

0.73

0.89

1.05

1.4

0.78

0.98

1.12

1.5

0.86

1.09

1.28

1.6

0.96

1.20

1.39

Caution

⚫

Be sure to use water when inspecting the spray

condition.

Caution

⚫

Do not switch between the two-way and

three-way switch nozzles while spraying. Doing

so may damage the switch nozzle.

⚫

Turn the two- or three-way switch nozzle to the

right to toggle.

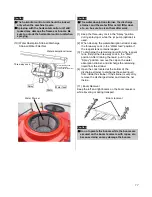

The figure above illustrates an optional three-way

switch nozzle type.

Assemble with the

discharge mark

facing downward.

Rice shower nozzle

Strainer (80 mesh)

Triple-cut gasket

Cap

Nozzle board

Gasket

Tang washer

Gasket

Gasket

Triple-cut gasket

Gasket

O-ring

Double-nozzle type