26

◼

Spray Plan

Warning

⚫

Make the spray planning so that there won

’t be

any chemical left.

(1) Spray Planning

In spray planning, determine the spray amount per unit

area (spray amount per 10 a) first, and then select the

spray speed and obtain the nozzle pressure. The

nozzle pressure can be obtained using quick

calculation diagrams.

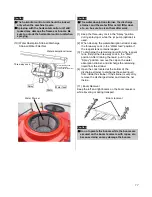

(2) How to Use the Quick Calculation Diagrams

You can use the quick calculation diagrams to obtain

the nozzle pressure with ease.

“Example”

[1] Spray speed: 2.7 km/h

[2] Spray amount: 100 L per 10 a

[3] Use a standard cone (ceramic)

1.6 nozzle.

[4] From the quick calculation diagrams, the nozzle

pressure is obtained as 1.6 (MPa).

Supplement

The quick calculation diagram assumes a tire

slip factor of 10% for the boom sprayer, taking

the nozzle loss rate, etc. into account.

Depending on the conditions of the field,

however, the tire slip factor of the boom sprayer

may change. In this case, the slip factor must be

corrected.

Depending on the state of the field, the tire slip factor

may vary and the spray speed may deviate, in which

case the nozzle spray amount must be set according to

these different slip factor/spray speed.

For more accurate spraying measure the actual slip

factor in the field.

⚫

Rough guide for slip factor

5% --- General crop field where the depth to the

furrow pan is approx. 10 cm

10% --- Field where the depth to the furrow pan is

approx. 15 to 20 cm (where a ride-on rice

planting machine can be used without

problems)

15% --- Field where the depth to the furrow pan is

approx. 20 to 25 cm

* Take note that the machine may not be able to travel

in a field where the depth to the furrow pan is 25 cm

or more. Also remember that the machine can travel

more smoothly when the field is filled with water.

Caution

⚫

When spraying in a field of a higher slip factor

(greater depth to the furrow pan), reduce the

amount of water added to the tank.

⚫

Adjust the nozzle pressure within a range of 1.0

to 2.5 MPa.