© Martin Engineering GmbH

30

M3682UK-09/17

Installation

5.2.8

Tensioning the secondary cleaner

.

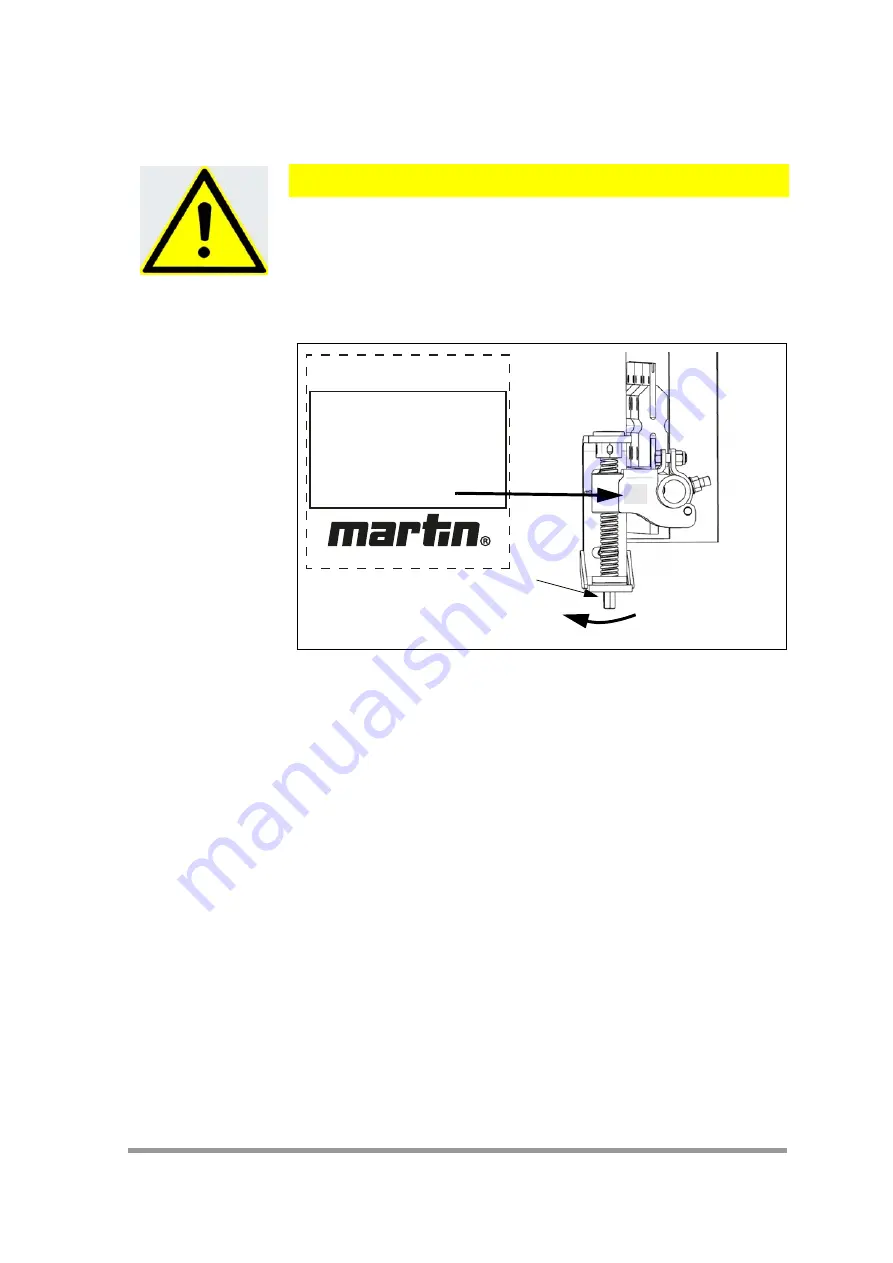

1. Before tightening, turn the lower hexagon of the threaded rod

(4, Fig.24) of the tensioner so far anticlockwise that the blades

touch both sides of the conveyor belt.

2. When all of the blades are touching the belt, tighten the cleaner

one-half to one rotation on both sides of the conveyor belt.

CAUTION RISK OF DAMAGE!

Excess or uneven tightening of the belt cleaner on the conveyor

belt can cause material damage.

Always tighten the belt cleaners in accordance with the

specification and also ensure uniform tightening whenever dual

Inline-Reversing tensioners are used. Note the information on the

warning label!

Fig. 24:

4

0049-(0)6123-97820 www.martin-eng.de

Recommended values of tension for

MARTIN® SQC2™ secondary cleaner

®

For cleaners with shock ring:

Turn the nut of the threaded rod until all blades

make contact with the conveyor belt uniformly.

To tighten, turn it by another half to full revolution.

For cleaners with urethane shock ring:

Turn the nut of the threaded rod until all blades

make contact with the conveyor belt uniformly.

To tighten, turn another 2 full revolutions.

Teilenr.: SQC2-10002UK

Summary of Contents for SQC2

Page 1: ...MARTIN SQC2TM Secondary cleaner Installation Instructions M3682UK...

Page 2: ...Martin Engineering GmbH M3682UK 09 17...

Page 54: ...Martin Engineering GmbH 52 M3682UK 09 17 Part numbers 9 9 SQC2 with SAF2 blades 0 5...

Page 63: ...Martin Engineering GmbH 61 M3682UK 09 17 Part numbers 9 12 SQC2 mini secondary cleaner 5 0...

Page 66: ...Martin Engineering GmbH 64 M3682UK 09 17 Part numbers 9 13 SQC2 tensioner...