MANDÍK CPV Installation, commissioning, and maintenance

IZU 02/2021

MANDÍK, a.s., www.mandik.cz

R

39

on dampers are manufactured from a material that does not require subsequent lubrication.

Use a lubricating spray on the lever mechanism on those dampers with lubricated lever

mechanisms.

Check the condition and operation of all condensate pans, the functionality of the pan drains

and the condition and functionality of the trap, and then clean and fill with water as needed.

Before winter, check the functionality of all freeze protection measures for the condensate

drain (if there is the potential for them to freeze).

9.12

ELECTRIC HEATER

The heating unit contains a heat exchanger with resistor elements, an operating thermostat set

to a fixed value of +50°C and alarm thermostat set to +80°C. The resistor rods are already wired

from the factory and are connected to the terminal blocks with the thermostats. The terminal

block is mounted to the heat exchanger on

the operator’s side.

Airflow of 1 m/s must be maintained at a minimum at all times for electric heaters under all

operating conditions and modes to ensure the heat from the heating elements is dissipated.

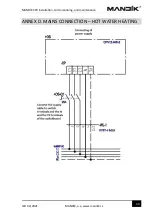

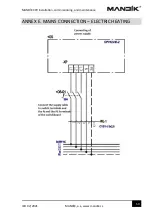

The electric heat exchanger is sized for 3~400 V / 50 Hz mains and may contain multiple

sections.

The surface temperature of the heating rods under operating conditions significantly exceeds

the safe contact temperature of 60°C. Allow a sufficient amount of time to enable the heating

rods to cool before starting any work or activities on the heaters!

Any intervention into electrical heaters may only be performed by personnel with professional

qualifications under the valid legislation in the country of installation of the equipment.

Check the condition of the heating elements and for any contamination, vacuum to clean as

needed.

It is necessary to check the operation of the operating thermostat and the alarm thermostat,

e.g. by manually adjusting the airflow.