MANDÍK CPV Installation, commissioning, and maintenance

IZU 02/2021

MANDÍK, a.s., www.mandik.cz

R

37

9.8

DAMPERS, FLEXIBLE ELEMENTS

Operable damper blades must be locked to prevent spontaneous or accidental closure. Never

put your fingers between the blades of an open damper as this is a serious injury hazard!

Check for dirt and grime, and any damage, and inspect the movement of the damper blades,

and the proper closure of the damper in particular. Vacuum up any dust and then wipe down

the surfaces of the damper blades using a damp rag. The plastic gears on dampers are

manufactured from a material that does not require subsequent lubrication. Use a lubricating

spray on the lever mechanism on those dampers with lubricated lever mechanisms. If a flexible

cuff is installed downstream of the damper, inspect it to ensure a proper seal and its integrity,

or clean if needed.

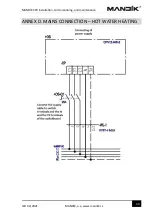

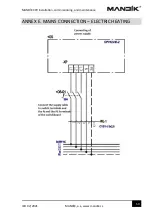

9.9

HOT WATER COIL, COLD WATER COIL

The surface temperature of the hot water coil and media conditions when in use may exceed

a safe contact temperature of 60°C. Before intervening or beginning any work in the

chamber, wait for the heat exchanger and connections to cool sufficiently.

Contact between bare skin and the heat transfer medium must be avoided when filling,

draining, and venting heat exchangers. When using additives or complete finished mixtures

for heating or cooling systems, follow all information provided by their manufacturers for the

use and handling of such substances.

Check heat exchangers for contamination, leaks and any damage. Remove any contaminants by

blowing down with compressed air or steam. In any case, ensure that the fins of the heat

exchanger are not damaged. and therefore high-pressure compressed air equipment should not

be used for such work.

Regularly check the connecting pipe for leaks and the functionality of all venting valves.

Independently of the defined maintenance intervals, and always before colder periods of the

year, check the functionality of all freeze protection devices, including a check of the antifreeze

solution concentration. Drain all the medium from cold water coils before winter and from all

heat exchangers prior to extended shut-downs (if not filled with an antifreeze solution of a

sufficient concentration). Draining of the medium does not guarantee that all liquid has been

drained from the heat exchanger and the heat exchanger must always be purged subsequently

using compressed air!

For cold water coils, also check the condition and operation of all condensate pans, the

functionality of the pan drains and the condition and functionality of the trap, and then clean

and fill with water as needed. Before winter, check the functionality of all freeze protection

measures for the condensate drain (if operated during winter and there is the potential for

them to freeze). Check for any deposits or other settled materials, and the condition and

cleanliness of the drip eliminator, which is to be removed and cleaned as needed.