[4] TROUBLE SHOOTING

Symptom

Cause

Corrective action

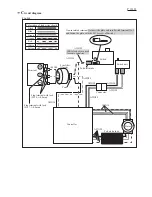

The Tester designates between

0.79 and 0.81V by the steps

shown in

Fig. T-3 of page 9

.

In case the tester is not ready,

go to “Yes”

Yes

Yes

Lamp (a) is ON.

See “Lamps on

Housing set”.

Yes

Yes

No

No

Lamps on Housing set

The function does

not have trouble.

Scratch on the core of

Rotor or mechanical

trouble is recognized.

In spite of the above corrective actions,

the machine shows same symptom.

Yes

Yes

No

No

No

No

All of Lamps (b), (c),

(d) are ON.

See “Lamps on

Housing set”.

Replace Controller.

Controller is broken.

Replace Stator complete*.

Controller is broken.

Replace Stator complete*.

Controller is broken.

Replace Stator complete.

Replace Stator complete*.

Replace Stator complete*.

Replace Rotor ass’y.

Controller is broken.

Replace Stator complete*.

Controller is broken.

Check the engagement of

Gears and Rotor ass’y or

condition of mechanical

parts.

Mechanical trouble

occurs.

Check Connectors,

or replace them.

Check Connectors or

replace them.

Lead wires are

disconnected.

Check Lead wires, or

replace the broken wire(s).

Lead wires are broken.

Check Lead wires, or

replace the broken wire(s).

Rotor ass’y is broken.

Stator complete is

broken.

Switch is broken.

Replace Switch.

Terminal is broken.

(a): Mode lamp (green)

If Green lamp is ON, the machine is

automatically set in High Torque mode.

(b),(c), (d): Battery power remaining lamp

All 3 stages of Battery power

remaining lamp are on.

See “Lamps on Housing set”.

Controller is broken.

P 8/ 11

R

epair

Whenever you find any trouble in your machine, first, refer to this list to check the machine for solution.

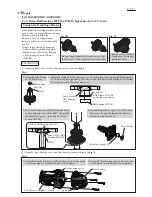

(1) Use the full charged battery which has the star mark. (

Fig. T-1

)

(2) When Housing is disassembled, check the conditions of the electrical parts

(Connectors, Lead wires, Switches, etc.), Armature, Stator complete, Gear section, etc.

Note

Check List for Trouble Shooting

Motor runs when the machine

is switched on (in forward and

reverse mode;10 times each)

In case of running inconstantly,

go to “No”.

Check the items from the top in

Fig. T-2

. (Description of the item is referred to Circuit

diagram in

Fig. D-1 of page 10

.)

Repeat the check of the corrective action ten times.

Check Terminal,

or replace it.

Connectors are

disconnected.

Connectors are

disconnected.

Star mark

Fig. T-1

Fig. T-2

*It includes Controller.