[3] DISASSEMBLY/ASSEMBLY

[3]-2. Spiral bevel gear 37, Ball bearing 696ZZ / 6201DDW (cont.)

[3]-3. Shaft lock mechanism

(1) Assemble Flat washer 12 and Ball bearing 6201DDW to Bearing box. (Refer to

Fig. 7 of page 5

.)

(2) Secure Ball bearing 6201DDW with Retaining ring R-32. (Refer to

Fig. 7 of page 5

.)

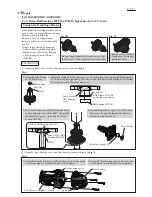

(3) Assemble Spiral bevel gear 37 to Spindle as drawn in

Fig. 8

.

(4) Reverse the disassembly procedure of

Figs. 7 and 6 of page 5

to set Bearing box section in place.

Remove Shaft lock mechanism (Shoulder pin 4, Compression spring 8 and Pin cap) as drawn in

Fig. 9

.

2. Put 1R029 on the area around the center

hole of Spiral bevel gear 37 and then

press it down.

3. Snap Ring spring 11 into the groove

of Spindle to secure Spiral bevel

gear 37, and then assemble Ball

bearing 696ZZ to Spindle.

1. Insert the thread of Spindle into

the hole on 1R036 to receive

the stepped portion of Spindle

as drawn below.

ASSEMBLING

DISASSEMBLING

Fig. 8

Fig. 9

1R036

1R036

Bearing box

Thread of Spindle

Stepped

portion of

Spindle

Spiral bevel

gear 37

Bearing box

1R029

1R036

Ball bearing

696ZZ

Ring spring 11

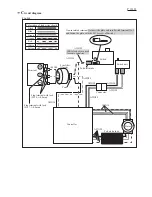

3. Apply 1R268 to Shoulder pin 4 through

the small hole on Pin cap and tap 1R268

with Metal hammer.

Shoulder pin 4 is removed from Gear

housing.

4. Release 1R268 from Pin cap

carefully so that Pin cap is not

slung by Compression spring 8.

Shoulder pin 4

Pin cap

Note

: Do not reuse Pin cap. It is because removal of

Shoulder pin 4 damages the inside surface.

(1) Clean up the plastic dust from Gear housing, Compression spring 8 and Shoulder pin 4. (

Fig. 11

)

(2) Assemble the components as drawn in

Fig. 12

.

1. Separate Gear section (Gear housing, Bearing

box) by unscrewing four 4x30 Tapping screws.

2. Separate Bearing box section from Gear housing

by unscrewing four M4x14 Pan head screws.

Small hole

of Pin cap

Compression

spring 8

1R350

Gear housing

Gear housing

Bearing box

Bearing box

4x30 Tapping

screws (4 pcs.)

M4x14 Pan head

screws (4 pcs.)

P 6/ 11

ASSEMBLING

Fig. 11

Fig. 12

Be sure to clean up

plastic dust here.

O ring 5

Shoulder pin 4

with O ring 5

Top of Shoulder pin 4

1. Insert Shoulder pin 4 through

the hole of Gear housing complete.

Pin cap

Compression Spring 8

2. Assemble Compression spring 8

and new Pin cap to Shoulder pin 4.

R

epair