Notch

Switch lever complete

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Rotor, Ball bearing 629LLB, 607LLB, Spiral bevel

gear 10 (cont.)

Fig. 3R

Fig. 3F

Caution for Handling of Rotor

When handling or storing multiple Rotors,

be sure to keep a proper distance between

Rotors as shown in

Fig. 3R

Because Rotor is a strong magnet,

failure to follow this instruction could

result in:

• Finger injury caused by pinching

between Rotors pulling each other.

• Magnetic loss of Rotors or damage

on the magnet portion of Rotor.

(

Fig. 3F

)

* Magnetic loss of Rotors

* Damage on the magnet

portion of Rotor

Ball bearing

607LLB

Rotor

1. Assemble Ball bearing

607LLB to Rotor.

(1) Assemble Rotor ass’y to Gear housing cover as drawn in

Fig. 4.

(2) Assemble Gear housing cover and Gear housing section as drawn in

Fig. 5.

4. Assemble Spiral bevel gear 10 to Rotor ass’y,

and secure the gear by turning M6 Hex nut

clockwise with Wrench 10.

Keep enough distance between Rotors so that

they are out of their magnetic forces each other.

ASSEMBLING

Spiral bevel gear 10

M6 Hex nut

Fig. 4

Fig. 5

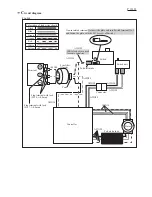

Gear housing

Spindle

Gear housing cover

2. Assemble Gear housing to Gear housing cover.

Face Spindle toward Switch lever complete.

1. Assemble Gear housing cover to Motor housing. Face the notch

of Gear housing cover toward Switch lever complete.

P 4/ 11

2. Assemble O ring 26 to the inner groove of Gear housing cover, and apply Makita grease

R No. 00 to the inner periphery of O ring 26, and then, insert Ball bearing 629LLB from

the large hole side of Gear housing cover.

3. Receive the inner race of Ball bearing 629LLB

in Gear housing cover with 1R027, and pressfit

the shaft of Rotor ass’y into the hole of Ball

bearing 629LLB.

Large hole of

Gear housing

cover

O ring 26

with Grease R No. 00

on the inner periphery

Ball bearing 629LLB

1R027

Hole of Ball bearing 629LLB

Inner race of Ball

bearing 629LLB

R

epair