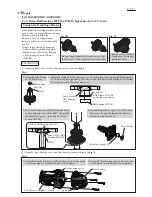

Fig. 13

1. Fit four projections on Housing set into four

mating cavities in Stator complete.

2. Be sure to align the center line of Bearing room

with the terminal of Stator complete.

Assemble Stator complete as drawn in

Fig. 13

.

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Stator complete

ASSEMBLING

Mating cavity on

the left side and

the right side

(tow each)

Terminal of

Stator complete

(Center line)

Projections in

Housing set

on the left side

and the right side

(two each)

P 7/ 11

R

epair

Bearing room

(to fit Ball bearing

607LLB of Rotor

ass’y) on Housing

set