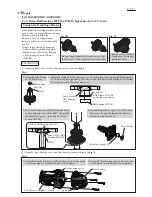

Fig. D-2

Wiring of Controller to Stator complete

Wiring after setting Switch and Switch unit

Pin A

Pin B

Boss for fitting

Switch unit

Boss A

Rib B

Rib A

Rib D

Boss B

Rib F

Rib E Connectors

Stator

Rib G

Controller

Terminal

Line filter (if used)

Rib H

Housing set R side

Housing set R side

Note

: Insert the plate end of Non-insulated terminal into Switch terminal No. 3

as drawn in

Figs. R

and D-1 of page 10.

Switch unit

Fig. R

Fig. F

Housing

set L

Housing

set L

Switch

Switch

Switch

Route lead wires (red, yellow, black) of Terminal

between Rib E and Rib F.

Put Line filter between Rib G and Rib H.

P 11/ 11

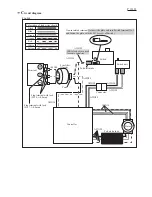

W

iring diagram

Bend thick lead wires (orange, white, blue) of Controller

here so as not to pinched between mating portions of

Housing L and R.

Fix Lead wires in these Lead wire holders one by one.

Route three thick lead wires (orange, white, blue)

of Controller between Pin A and Pin B.

Route Polyolefin tube of Controller between;

• Rib A and Boss A

• Rib B and Boss for Switch unit fitting

• Rib B and Rib D

• Pin A and Boss B

Put Connectors (of Lead wires

for Switch unit and Controller)

in this space.

Fix Lead wires from Switch unit

in these Lead wire holders.