506326-01

Page 9 of 20

Issue 0941

Air Filter

All indoor return air must be filtered. A washable filter is

furnished with the unit, located in the return air opening.

Provisions must be made to accommodate filter servicing.

The filter should be cleaned at least three times during each

of the heating and cooling seasons, or more frequently if

unusual conditions are encountered. To clean the washable

filter, shake filter to remove excess dirt

and/or use a vacuum cleaner. Wash filter in soap or detergent

water and replace after filter is dry. It is not necessary to oil

the filter after washing.

If an installation is made in which it is more desirable to

mount the filter exterior to the unit, in the return duct work or

elsewhere, the washable filter can be used or replaced with

a disposable filter. If a disposable filter is used, use the

information provided in Table 4 when sizing the disposable

filter. These units are not designed for high static filtration.

Condensate Drain

Provisions must be made to properly drain the indoor and

outdoor drain pans of this appliance.

The indoor drain pan drains internally into the outdoor drain.

The outdoor drain connection is a 3/4" NPT to 3/4" PVC fitting

(schedule 40 minimum). The drain size should not be reduced.

The drain must be trapped as shown in Figure 7. The drain

line should pitch gradually downward at least 1" per 10' of

horizontal run to open drain.

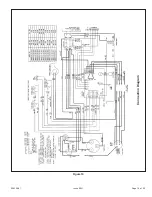

Electrical Connections

All wiring must be done in accordance with the National

Electrical Code (NEC), ANSI/NFPA No. 70 (latest edition);

Canadian Electrical Code CSA C22.2 Part 1 (latest edition);

or local codes, where they prevail. Any alteration of internal

wiring will void certification and warranty. Units are factory

wired for a 230 volt single phase power supply. If power

supply is 208 volts, it will be necessary to change a wire

connection on unit transformer from 240 volt terminal to 208

volt terminal as shown on the wiring diagram.

Use wiring with a temperature limitation of 75°C minimum.

Run the 208 or 230 volt, 60 hertz electric power supply

through a fused disconnect switch to the control box of the

unit and connect as shown in the wiring diagram located on

the inside of the control access panel.

The unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

or CSA C22.2 Part 1 (latest edition).

Power supply to the unit must be NEC Class 1 and must

comply with all applicable codes. A fused disconnect switch

should be field provided for the unit. The switch must be

separate from all other circuits. If any of the wire supplied

with the unit must be replaced, replacement wire must be of

the type shown on the wiring diagram.

Electrical wiring must be sized to minimum circuit ampacity

marked on the unit.

Use copper conductors only.

Each

unit must be wired with a separate branch circuit and be

properly fused.

Figure 7

Condensate Drain Installation

Use thread sealant on the threaded fittings. Install

threaded fittings by hand only.

Do not overtorque the

fittings.

CAUTION

Minimum Required Surface Area

for Disposable Filters

Table 4

* 9 and 10 EER models

Model Number

Filter Area

MGE*12

MGE*18

MGE*24

MGE*30-36

192 Square Inches

288 Square Inches

384 Square Inches

480 Square Inches