Page 6 of 20

506326-01

Issue 0941

3.

Remove the 5/16" screw used to mount the vent pipe

assembly to the mounting bracket. Keep this screw.

4.

Five holes have been drilled into the vent extension (see

Figure 4). Four of those holes are provided so that the

vent can be extended the necessary length required for

the installation. The wall sleeve that is installed

determines which of these clearance holes should be

used. Using Table 2 and Figure 4, determine which

clearance hole should be used to position the vent

extension properly. Slide the vent extension outward and

line up the correct clearance hole on the vent extension

with the hole in the vent pipe and the hole in the mounting

bracket.

5.

Re-install the 5/16" screw that was removed in Step 3.

Thread the screw first through the clearance hole in the

mounting bracket, the proper clearance hole in the vent

extension, and into the engagement hole in the vent

pipe. The length of the vent pipe extension that extends

out of the cabinet should be as shown in Table 2.

6.

Position the vent pipe at the center of the steel insert

when using poly louvers. The vent pipe should have a

slight downward slope to allow any moisture to drain

away from the unit as well as being centered on the

metal grate.

I

nstalling and Securing Unit to Wall Sleeve

Before installing and securing the unit to the wall sleeve,

make sure that the proper louver kit is installed. Due the

high temperatures of the combustion products released from

the gas vent, MGE gas package units require the use of

either an aluminum louver kit or special MGE polypropylene

louver kit (see

ACCESSORIES

on page 17).

1. Make sure the gaskets attached to the sleeve are not

damaged.

2.

Verify divider panel is positioned properly. Figure 5 shows

the correct position for 60" and 64" tall units (flange

pointing up). For 58" tall units, the divider panel should

be positioned so the flange points down.

1.

Access vent pipe at the side of the unit that will face the

outdoors.

2.

The vent pipe and vent pipe extension is located to the

right of the outdoor fan (see Figure 3).

Vent Pipe Installation

Determining the length of the vent pipe extension is

dependent upon which wall sleeve accessory is installed at

the job site for each particular installation.

For proper operation, the vent length must be correct for

the installation. The unit may not operate correctly with

inadequate vent length.

CAUTION

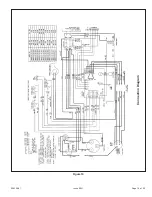

Figure 3

Locating Vent Pipe and Extension

Mounting

Bracket

Vent Pipe

Outdoor Fan

Positioning Vent Pipe Extension

Figure 4

* The clearance holes are not marked on the actual

vent extension.

Outdoor Fan

0

Vent Extension

Clearance Holes*

Determining Hole Setting

Table 2

ASLEEVE12-1, 2, 3, 4

Hole

#

Wall Sleeve Used

Approximate

Length the Vent

Extends from

the Cabinet

ASLEEVE6-1, 2, 3, 4

ASLEEVE8-1, 2, 3, 4

ASLEEVE10-1, 2, 3, 4

ASLEEVE2-1,2

4

3

2

1

0

5.5 Inches

7.5 Inches

9.5 Inches

11.5 Inches

0 Inches