Note:

If the maximum boiler output capacity is required, any logs with larger diameters are necessary to be

cut in half or, possibly, cut in quarters.

3.

Technical Description

The boiler is designed to work on wood combustion. The combustion process (which is based on power generating

gasification) is obtained by passing ambient air into the firebox (furnace) with the use of an exhaust fan.

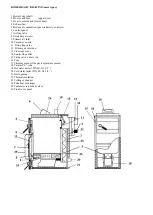

The boiler shell is made from steel plates as a welded assembly. It consists of a fuel feed hopper, which at its bottom part

is equipped with a fireproof insulation brick that comprises a longitudinal opening (nozzle) for exhausting the combustion

products. There is an afterburning space with ceramic tile blocks located beneath the said fireproof insulation brick. In the rear

part of the boiler there is a vertical tube plate that, in its upper part, merges into a collecting duct where there is a firing valve.

The collecting duct’s rear part is equipped with an exhaust fan and socket for connecting the duct to the chimney.

The front face of the upper part comprises a refueling door and the lower part comprises an ash door. There is a fan

located on the back side.

The outside surface of the boiler body is thermally insulated with mineral wool inserted beneath sheet metal covers of the

boiler’s outer shell.

The upper portion of the boiler comprises a control panel.

The boiler’s construction gives the following advantages:

- the combustion process takes place at a high temperature using the function of power generating gasification;

- the combustion air is supplied through an exhaust fan;

- the combustion process is characterized with stable flame and a stable state and quality of combustion;

- the large fuel feed hopper enables the burning of separate pieces of wood with maximum length of 500 mm (MA15 – 350mm,

MA 80 up to 650 mm);

- enables the burning of wood waste.

4.

Operating Regulations

Boiler Preparation for Operation

Before the boiler is put into operation, it is necessary to ensure that your heating system has been filled with water (that

has to be up to standard STN 07 7401:1992) and deaerated. Ceramic “U” needs to be completed and has to be placed directly

under the nozzle – (see page 8). There is also an electrical box at the back side of the boiler, which has a terminal board for

connection of the water pump(inclouded socket). The preset value is 50°C.

In order to ensure proper and safe operation, your wood-fired boiler must be operated in accordance with the instructions

contained in this operating and maintenance manual. The boiler must be operated by adults only.

CAUTION

When you fire up a new boiler for the first time, condensation and discharge of the condensate from the boiler may occur

- this is not because of any defect in the boiler. After a longer duration of operation the condensation will disappear.

Boiler Cleaning

The cleaning of a boiler should be carried out as follows: Open the feeding door (2) and then sweep the ash through the

slot (10) into the lower space. Small pieces of unburnt wood (i.e. wood coal) can be left in the charging hopper until the boiler is

fired up next time. Open the clean-out opening (13) and clean the tube plate by taking out of the turbulators (25) and cleaning by

the tube cleaner. After you open the ashtray door you can rake the ash and soot out from the ashtray.

A cleaning interval depends on the quality of fuel you use (moisture content), the intensity of heating, the chimney

draught, and other specific circumstances. The boiler should be cleaned at least once a month. The lower combustion space is

necessary to be kept clean. You should clean it twice a week, at the least.

Minimum once a year, we recommend to clean the wheel of the exhaust fan(4) and the air ways. We should turn off the

control unit and unplug the boiler from the electricity. We can demount the exhaust fan by unscrewing 4 screws under the

chimney tube (14) and take out the exhaust fan with the sheet metal plate it is mounted on. Be careful and do not break the

electrical cable it is connected to the boiler. We can clean the wheel by a soft or medium brush. The we mount the fan the same

way we have demounted it. Electrical cables should hang from the bottom of the fan. To clean the air ways, we must demount

the front panel (26), unscrew two screws under the upper door (2) and 2 screws on the panel’s sides. Unscrew the air flap valve

(7) and clean the air ways. Use a plug for the holes for air ways into the nozzle, to keep it clean from the ash from the cleaning.

After cleaning, unblock the air way into the nozzle and mount the parts in the same order from the end to the beginning.

5.

Heating System and Boiler Maintenance

You should check the water level in the heating system at least once in every 14 days. Refill water if necessary. Refilling

must be, at all times carried out with the boiler out of operation. If, during winter season, your boiler is out of operation, there is

a danger that the water remaining in the system may freeze causing damage to the system. In this case we can use an anti-freeze