214880

80

Revision A

4.5.3

Replacing Cutterbar Spindles

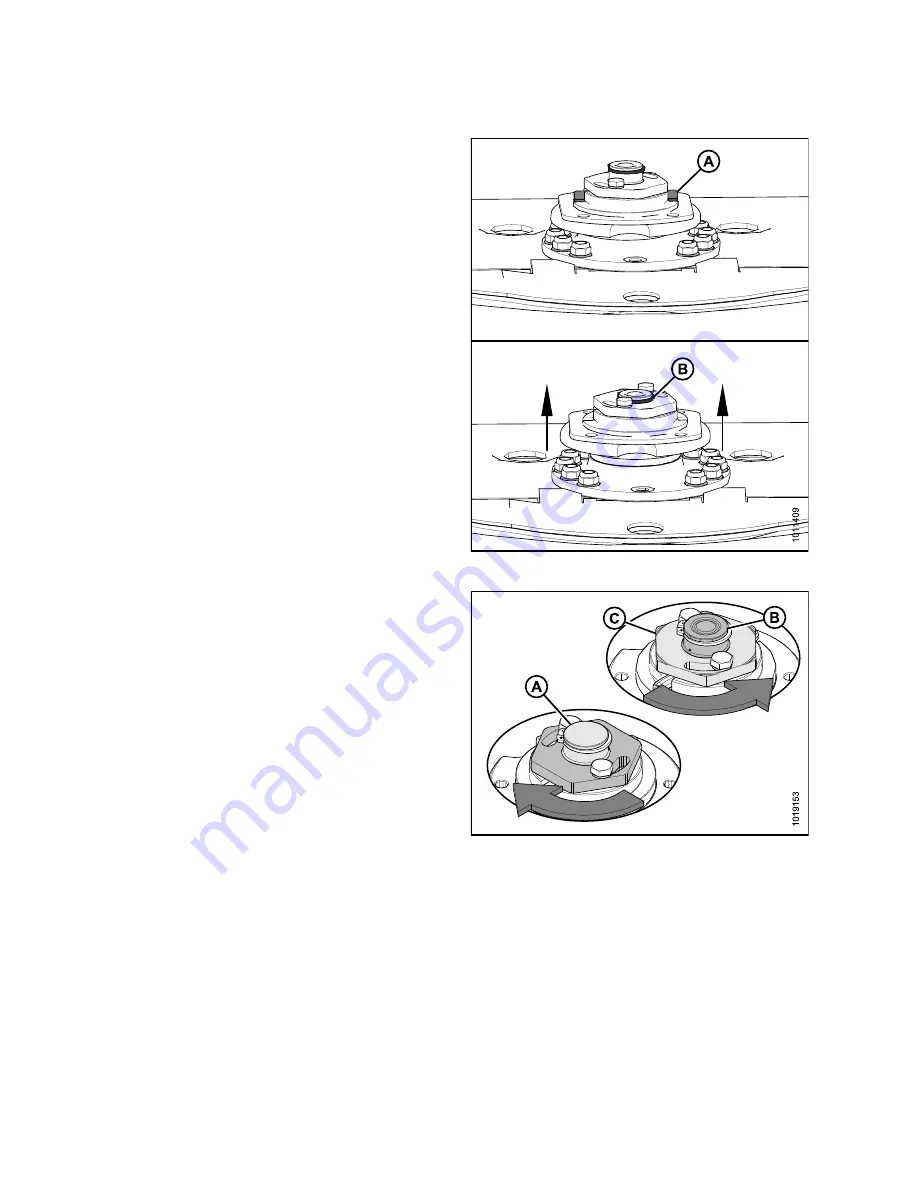

Figure 4.26: Cutterbar Spindles

To prevent damage to the cutterbar and drive systems, each

disc is attached to a spindle containing a shear pin (A).

If the disc contacts a large object such as a stone or stump, the

pin will shear and the disc will stop rotating and move upwards

while remaining attached to the spindle with a snap ring (B).

NOTE:

Once spindle has risen due to shear pin failure, the spindle

’

s

bearing will become unloaded. Do

NOT

replace the spindle due

to excessive play. Check play after torquing spindle nut and

replacing damaged shear pins.

Refer to

4.5.8 Replacing Cutterbar Spindle Shear Pin, page 116

to replace shear pin.

Figure 4.27: Cutterbar Spindles

IMPORTANT:

•

Spindles that rotate clockwise have right-leading threading

and are identified by a smooth top on the spindle gear

shaft (A).

•

Spindles that rotate counterclockwise have left-leading

threading and are identified by machined grooves on the

spindle gear shaft (B) and nut (C).

•

If spindle position in cutterbar has changed, the rotational

direction of that spindle

MUST

remain the same (that is, a

clockwise spindle must maintain its clockwise rotation).

•

Failure to maintain rotation pattern can result in damage to

spindle and/or cutterbar components.

•

Safecut (shear pin) will not work if spindles are used in the

wrong orientation.