800.MACTOOLS

39

Voltage Load Test Battery Voltage Vs Battery/Air Temperature

Meter Reading

Battery/Air Temperature

10.0V

90°F/33°C

9.8V

80°F/27°C

9.6V

70°F/21°C

9.4V

60°F/16°C

9.2V

50°F/10°C

9.0V

40°F/4°C

8.8V

30°F/-1°C

8.6V

20°F/-7°C

NOTE:

The above table is only for non-critical reference.

Battery temperature can be checked by using the meter’s temperature function.

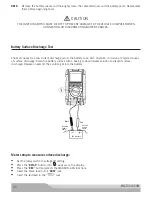

VOLTAGE DROP TESTS

Voltage drop tests measure the amount of voltage expended to overcome resistance (an opposing force to

the flow of electrical current created by a circuit or component); the lower the voltage drop reading, the less

resistance in the circuit under test.

The Hold function and the MAX/MIN Record function are very useful for measuring voltage drops on many

different components and connections. For example, measuring the voltage drop across the connections and

components in the starter circuit while cranking the engine (ignition or fuel system disabled to prevent starting)

allows you to determine if there is excess resistance in the starter circuit.

To measure voltage drop, current must be flowing in the circuit and both voltage test probes must be connected

on the same side of the circuit. Voltage drop can also be determined from available voltage readings by noting

the difference between each successive reading.

Refer to the vehicle manufacturer’s specification for voltage drop information. If the voltage drop specification

is not available, refer to the following table to determine typical voltage drop for 12V systems:

Typical Allowable Voltage Drop

Component

Typical Voltage Drop

Battery cable length up to 3 feet

0.1V

Battery cable length over 3 feet

0.2V

Magnetic switches

0.3V

Solenoid switches

0.2V

Mechanical switches

0.1V

Battery cable connectors

0.05V

Connections

0.0V