DP16-910B-VS 11

Adjusting the quill return spring

NOTE

: The return spring tension is set at the

factory and should not require further

adjustment.

1.With the chuck at its highest possible position,

turn the depth scale clockwise until it stops and

tighten the depth scale lock knob. This will

prevent the quill from dropping while tensioning

the spring.

2.Lower the table for additional clearance.

3.Work from the left side of the drill press.

4.Place screwdriver in the lower front notch

Fig.20 of the spring cap), and hold it in place

while loosening and removing the outer nut

(only).

5.With screwdriver remaining in the notch,

loosen inner nut (approx. 1/8”) until the notch

disengages from the boss on the head. Do not

remove this nut.

6.Carefully turn screwdriver counterclockwise

and engage the next notch in the boss. Do not

remove screwdriver.

7.Tighten nut with wrench only enough to

engage boss. Do not over tighten as this will

restrict quill movement.

8. Check tension while turning feed handles.

9.If there is not enough tension on the spring,

repeat step 4-8 moving only one notch each time

and checking tension after each repetition.

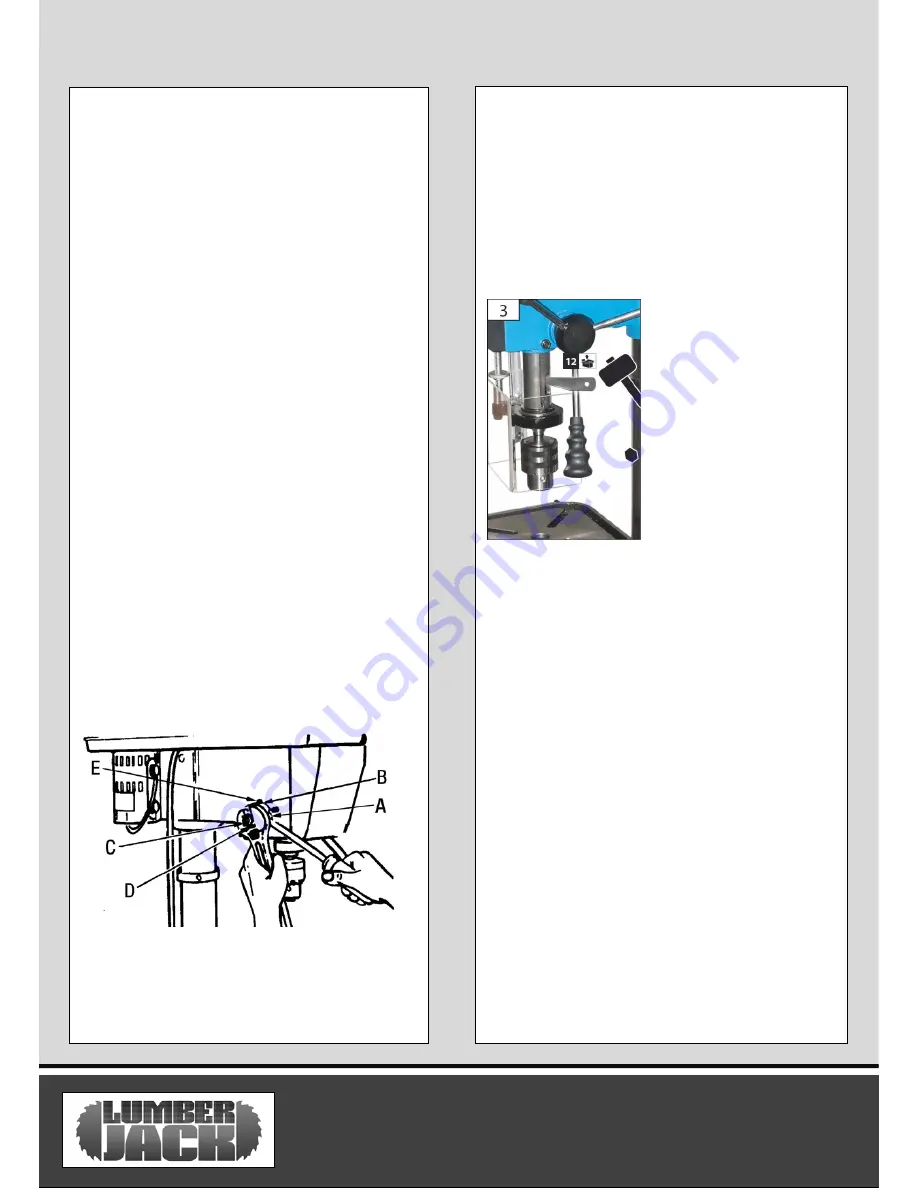

Removing the chuck & arbor

1. Align key holes in spindle and quill by rotating

the chuck by hand.

2. Insert drift key into key holes in the quill.

3. Tap key drift key lightly until the chuck and

arbor fall out of the spindle.

NOTE:

Place one hand below the chuck to catch

it when it falls out.

ADJUSTMENTS

Summary of Contents for DP16-910B-VS

Page 23: ...DP16 910B VS 21 Parts Diagram...