ENGLISH

13

14.3 WORK PROCESS - MESSAGES

1.

Insert the plug into an outlet.

2.

Press the main switch [green] ON/OFF to ensure that the green control lamp is illuminated.

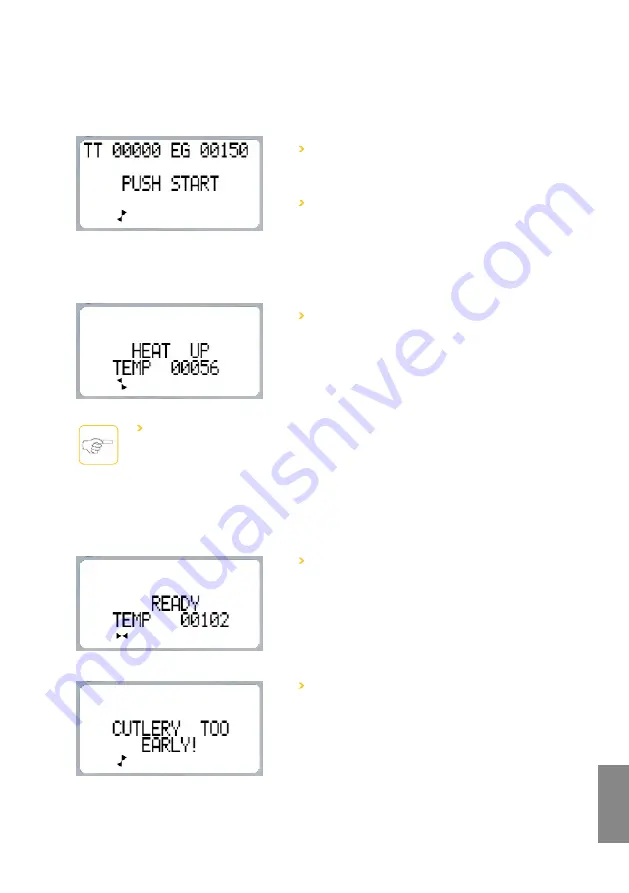

Electricity is now supplied to the machine. The following message will be shown on the display:

3.

Press the START/STOP button [(1)] to ensure that it is illuminated red. The vibration motor

switches on now and the following messages will be shown on the display:

4.

In the meantime, place a collection container for the flatware (not too low to prevent noise

and damages to the flatware) underneath the discharge opening.

1st Line: Display of the total previous operating hours

and the remaining operating hours until the next required

granulate exchange.

2nd Line: „Press start“ command

The heating phase starts and the polishing machine starts

vibrating as soon as the START/STOP button [(1)] has been

activated. The button flashes red until the phase has been

completed. The granulate will be heated to a temperature

of app. 115° C during this waiting time.

Note:

Depending on the ambient temperature, the operating temperature is reached after app. 10 to

15 minutes. Temperature variations of +/- 4 °C (due to an active/inactive heating) are normal.

If the operating temperature has been reached the message

„READY FOR OPERATION“ appears. The temperature is shown

on the second line. The machine switches automatically to post

drying if no polishing process occurs after two minutes. If the

post drying time has been completed, then the machine swit-

ches off, however, the electrical power supply remains connected.

If the flatware is inserted during the heating phase, then the

message „FLATWARE TOO EARLY“ appears accompanied by

several short sound signals. Therefore, a flawless polishing result

cannot be guaranteed based on the low temperature.