OM-LKT-45G 15

Maintenance

4. jacket Filling

The jacket was charged at the factory with the proper amount of treated

water. You may need to restore this water because it was lost as steam during

venting. Every day, before you turn on the unit, make sure the water level is

approximately in the center of the water level sight glass (See Photo 10-2 on

page 10).

a. If you are replacing water lost as steam, use distilled water.

do not use

tap water.

If you are replacing treated water that was drained from the

jacket, contact LoLo Service Support at 877-246-5656.

b. Allow the kettle to cool completely. Remove the pipe plug from the jacket

fill assembly.

c.

Open the gate valve and pour in the distilled.

TIP

: Using a funnel will help

you in this process. Hold the pressure relief valve open while you pour, to

let air escape from the jacket.

NOTE

: The low water light (red indicator lamp) comes on when the level

drops below the minimum line on the sight glass. Refill with distilled water

until the level returns to between the MIN and MAX marks on the water

sight glass.

d. Close the gate valve and replace the pipe plug.

e. Air that gets into the jacket during the filling operation must be removed,

because it will make heating less efficient. Follow the procedure in

Jacket Vacuum - Removing Air From Jacket to restore a negative pressure

(vacuum) reading.

ImPORTANT

: If most or all of the jacket water is lost due to a leak, contact

LoLo at 877-246-5656 or your LoLo authorized service provider. The

source of the leak will need to be determined and repaired; and the kettle

jacket refilled with chemically treated water.

5. lubricate Tilt mechanism

The gear housing has fittings for lubrication of moving parts. The gears do

not run in oil, so periodic lubrication with grease is necessary. Frequency of

lubrication depends on operating conditions, but

it should be done at least

once every six months.

a. Use a #2 grade LGI lithium grease to add grease through Zerk fittings on

gear housing until it flows out of the bearings around the trunnion shaft.

b. Place liberal amounts of grease on the gear to cover the arc that is in

contact with the worm gear.

c.

Keep the inside of the control console clean and dry.

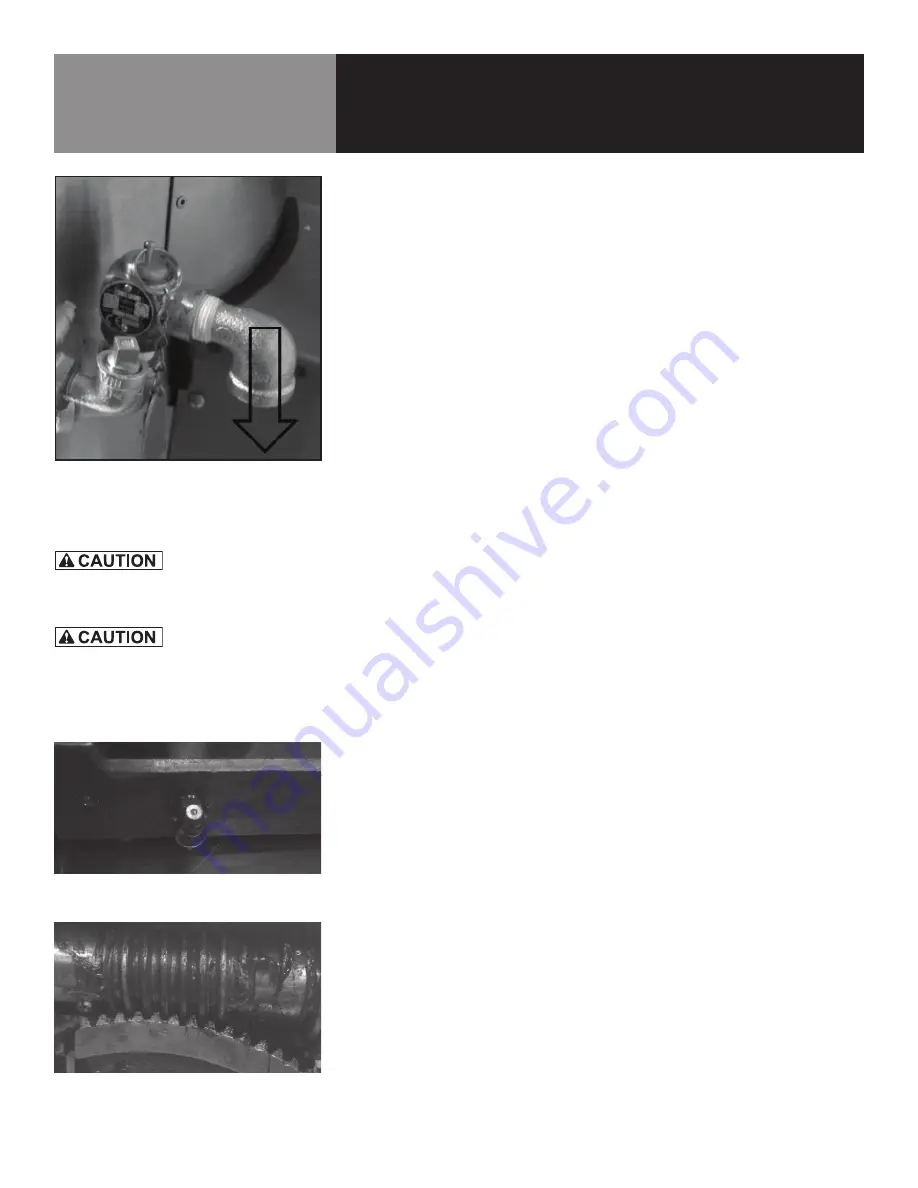

Photo 15-1

Make sure that the open end of

the elbow on the pressure relief valve

is directed downward.

KEEP gREASE AwAY FROm ElECTRICAl

PARTS lOCATEd NEAR ThE gEARS.

TO AvOId INjURY, REAd ANd FOllOw

All PRECAUTIONS STATEd ON ThE

lAbEl OF ThE wATER TREATmENT

COmPOUNd.

Photo 15-2

Add grease through Zerk fittings.

Photo 15-3

Liberally grease the large gear segment

where it contacts the worm gear.