Installing the battery

W

hile the RailSounds sound system is powered through the track, we recommend that you

install a nine-volt alkaline battery in the tender to prevent the sound system from

shutting down during track power interruptions (for example, at a switch or a dirty section of

track). Follow these steps and refer to Figure 3 on page 9 as you install the battery.

If the RailSounds sound system turns off during interruptions in track power, you

may need to replace the battery.

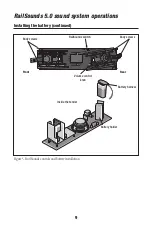

1. Remove the body screws from the underside of the tender. Refer to Figure 3 on page 9 for the

location of the screws.

2. Lift the body off the frame. Be careful to avoid pulling on the wires that connect the body to

the frame.

3. Remove the protective cover from the battery harness.

4. Snap the battery harness onto the nine-volt alkaline battery’s terminals.

5. Slide the battery into the battery clip.

6. Replace the body on the frame and secure it with the body mounting screws. Be careful to

avoid pinching any wires between the body and the frame.

Note!

8

RailSounds 5.0 sound system operations

RailSounds 5.0 sound system operations

Y

our locomotive is equipped with the Lionel RailSounds 5.0 sound system, the most realistic

model railroad sound system in the world. The RailSounds 5.0 sound system brings the

sounds of the railroad to your layout through high quality sound recordings of real locomotives.

When you operate your locomotive in the conventional environment, you get realistic

chuffing sounds, which automatically increase through 15 levels as the speed of the locomotive

increases. You can sound the locomotive’s whistle or activate the ringing of the bell. When you

are through with operations and power down the track, your locomotive’s RailSounds 5.0 sound

system starts a realistic steam shutdown sequence (a nine-volt battery is required for the

operation of the RailSounds 5.0 sound system when the track is powered down).

When you operate your locomotive in the TrainMaster Command Control environment, you get

full control of the RailSounds 5.0 sound system, including the whistle and bell sounds. The

locomotive’s chuffing sounds automatically increase, but you can also set a particular chuff intensity

level using your CAB-1 Remote Controller. In the Command Control environment, the release of the

ElectroCoupler is accompanied by a coupler release sound. Use the

BRAKE

button, and listen for the

sound of squealing metal. You can also trigger CrewTalk dialog and TowerCom announcements,

which simulate the interaction between the locomotive crew and the dispatcher. Whenever you choose

to shutdown your locomotive, the realistic shutdown sequence commences (a nine-volt battery is

required for the operation of the RailSounds 5.0 sound system when the track is powered down).