– –

– –

30

31

Resources

Support

For technical support, product documentation, application notes, regulatory

guidelines and software updates, visit www.linxtechnologies.com

RF Design Services

For customers who need help implementing Linx modules, Linx offers

design services including board layout assistance, programming,

certification advice and packaging design. For more complex RF solutions,

Apex Wireless, a division of Linx Technologies, creates optimized designs

with RF components and firmware selected for the customer’s application.

Call +1 800 736 6677 (+1 541 471 6256 if outside the United States) for

more information.

Antenna Factor Antennas

Linx’s Antenna Factor division has the

industry’s broadest selection of antennas

for a wide variety of applications. For

customers with specialized needs, custom

antennas and design services are available

along with simulations of antenna performance to speed development.

Learn more at www.linxtechnologies.com.

by

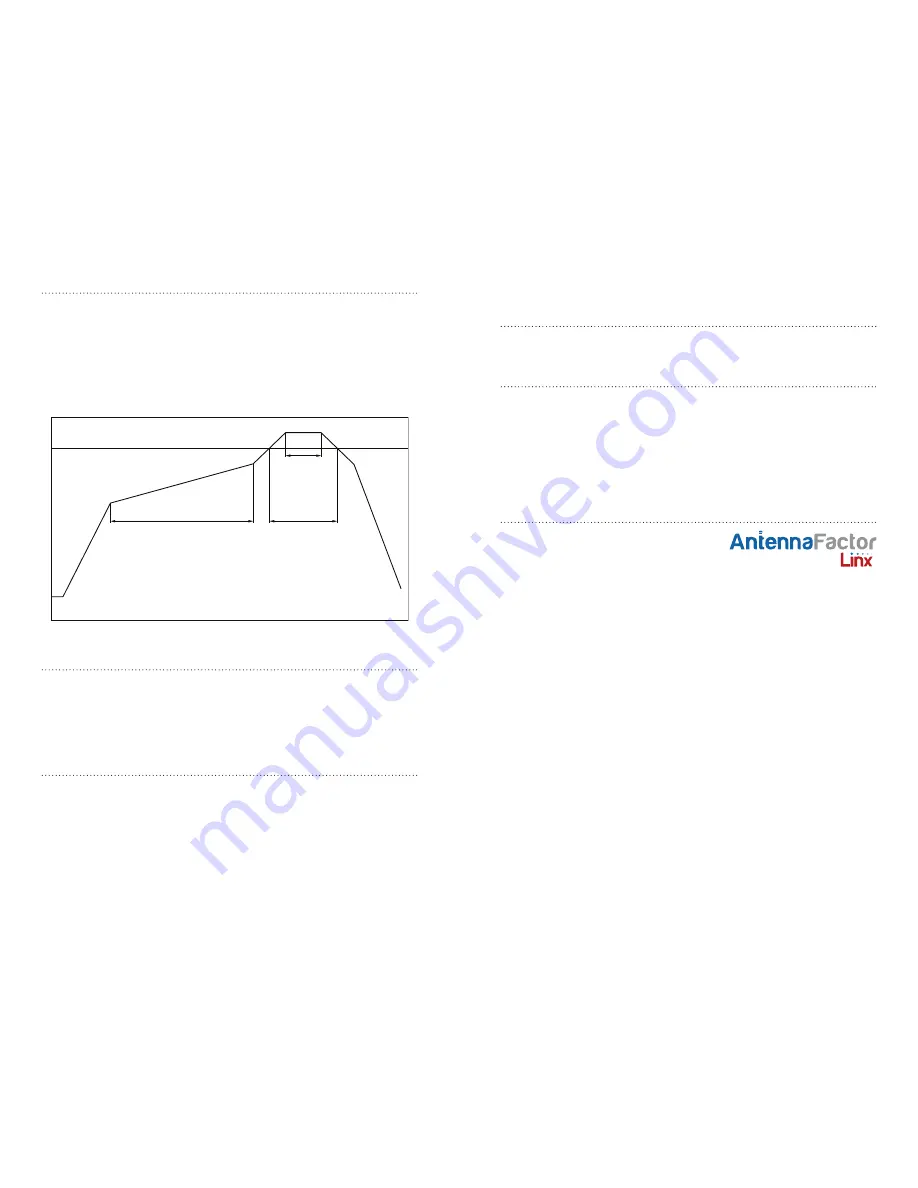

Reflow Temperature Profile

The single most critical stage in the automated assembly process is the

reflow stage. The reflow profile in Figure 36 should not be exceeded

because excessive temperatures or transport times during reflow will

irreparably damage the modules. Assembly personnel need to pay careful

attention to the oven’s profile to ensure that it meets the requirements

necessary to successfully reflow all components while still remaining

within the limits mandated by the modules. The figure below shows the

recommended reflow oven profile for the modules.

Shock During Reflow Transport

Since some internal module components may reflow along with the

components placed on the board being assembled, it is imperative that

the modules not be subjected to shock or vibration during the time solder

is liquid. Should a shock be applied, some internal components could be

lifted from their pads, causing the module to not function properly.

Washability

The modules are wash-resistant, but are not hermetically sealed. Linx

recommends wash-free manufacturing; however, the modules can be

subjected to a wash cycle provided that a drying time is allowed prior

to applying electrical power to the modules. The drying time should be

sufficient to allow any moisture that may have migrated into the module

to evaporate, thus eliminating the potential for shorting damage during

power-up or testing. If the wash contains contaminants, the performance

may be adversely affected, even after drying.

Preheat:

150 - 200°C

Peak: 240+0/-5°C

25 - 35sec

220°C

2 - 4°C/sec

120 - 150sec

2 - 3°C/sec

60 - 80sec

30°C

Figure 36: Maximum Reflow Temperature Profile