Linddana A/S

. Ølholm Bygade 70 . DK-7160 Tørring . T +45 75 80 52 00 . [email protected] . www.linddana.com

Brugsanvisning: TP 230 fra dato 02.11.2015 ©Copyright 2008

20

8.3.4

Scrapers and blanking plate

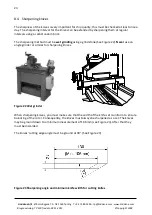

The machine is equipped with three square scrapers on the rotor disc, one triangular scraper in

the rotor housing and a blanking plate in the ejector tube (see Figure 19):

Figure 19 Location of scrapers and blanking plate

The purpose of the scrapers is to remove material that may jam the knives.

At the same time the square scraper on the rotor removes material that falls off before the

cutting disc.

This reduces the wear on the casing and reduces the fuel consumption.

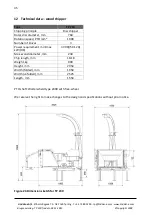

The square scrapers can be turned once before they must be replaced, while the triangular

scraper and blanking plate must always be replaced once they become worn.

What to do:

Turn the rotor until the rotor locking bolt connects with one of the ejector blades on the rotor.

The rotor is now locked

(see Figure 14).

Remove the countersunk bolts holding the square scraper in place on the rotor. Turn the square

so that a sharp corner points upwards. Clean the block and contact surface. Replace the square

scraper. If it is worn on two corners, the square scraper must be replaced. Always replace the

square scrapers on the rotor as a set. Replace the triangular scraper once it becomes worn.

The blanking plate is installed in the top section of the rotor housing and can easily be replaced by

removing three bolts on the outside of the rotor housing. If chip quality is not of crucial

significance, it can be beneficial to remove the blanking plate in the ejector tube. This will increase

the capacity of the machine and save fuel. The blanking plate must be removed when chipping

wet softwood with numerous needles. This ensures good discharge.

Once the scrapers have been turned or replaced, turn the rotor several revolutions to ensure that

it runs freely and there are no loose objects in the rotor housing. Now close the rotor housing and

tighten the bolts (See Figure 13).