Linddana A/S

. Ølholm Bygade 70 . DK-7160 Tørring . T +45 75 80 52 00 . [email protected] . www.linddana.com

User instructions: TP 230 from 02.11.2015

©Copyright 2006

12

7

Operation of the machine

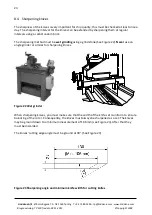

The wood chipper is equipped with two hydraulic rollers, pressure-compensated flow valve,

control valve and operating guard on the feed funnel (See Figure 6). The feed funnel can be tilted.

The operating guard must be in the stop position (0) during start-up (See Figure 7). After start-up,

pull the operating guard to the central position (A) and the rollers will turn. The material will now

be drawn into the machine.

Drawing the operating guard all the way towards you (B) will reverse the oil flow in the control

valve, reverse the rollers, and the material will now run out of the machine.

Figure 8 Feed funnel TP 230 with operating

guard

Figure 9 Directions for the operatin

By adjusting the adjusting screw on the flow valve, you can determine the correct rotation speed.

Never run the rollers too fast, as the wood, together with too much pressure on the rotor, will act

as a brake, resulting in increased fuel consumption. Branches can wind around the rollers if the

rotation speed of the rollers is too fast.

The table below (Table 1) shows the recommended rotation speeds of the feed rollers for the

required chip length. The speed varies with the rotation speed of the PTO shaft. The chip length

can be regulated using the wood chipper’s flow regulation valve for chip lengths smaller than

specified in the table.