English

English

13

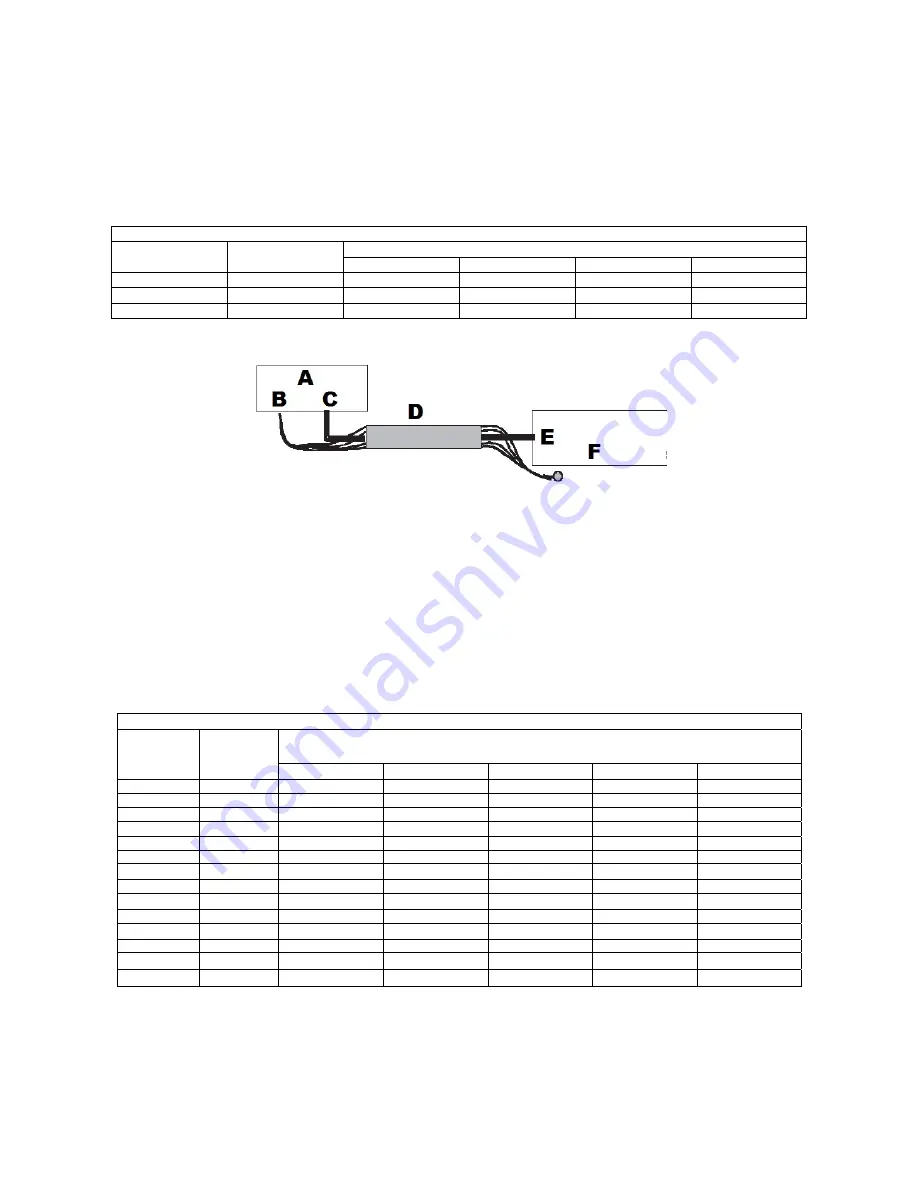

To install: (See figure #31)

1. Turn the input power off at the welding power source.

2. Connect one end of the center lead to the power source electrode connection, and the other end to the wire feeder

electrode connection.

3. Connect the outer lead bundle to the power source work connection, and the other end to the work piece. Minimize

the length of any work lead extension for best results.

4. Insulate

all

connections

Table 1

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 75°C)**

AMPERES DUTY

CYCLE

COAXIAL CABLE LENGTH

0m to7.6m

7.6m to 15.2m

15.2m to 22.9m

22.9m to 30.5m

250

100%

1 1 1 1

300 60% 1

1

1 1/0

350 60% 1/0 1/0 --

--

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C)

may require cables larger than recommended, or cables rated higher than 167°F(75°C).

A. Power

source

B. Work

C. Electrode

D. Coaxial

weld

cable

E. Electrode

F. Wire

feeder

G. work

Figure #31

Weld Cables, Standard

Table 2 has copper cable sizes recommended for different currents and duty cycles. Lengths stipulated are the distance

from the welder to work and back to the welder again. Cable sizes are increased for greater lengths primarily for the

purpose of minimizing cable drop

Table 2

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 75°C)**

AMPERES

PERCENT

DUTY

CYCLE

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK

CABLES

0 to 15m

15 to 30m

30 to 46m

46 to 61m

61 to 76m

200 60

35mm2 35mm2 35mm2 50mm2 70mm2

200 100

35mm2 35mm2 35mm2 50mm2 70mm2

225 20

25mm2 35mm2 25mm2 50mm2 70mm2

225

40 & 30

35mm2 35mm2 35mm2 50mm2 70mm2

250 30

35mm2 35mm2 35mm2 50mm2 70mm2

250 40

35mm2 35mm2 50mm2 50mm2 70mm2

250 60

50mm2 50mm2 50mm2 50mm2 70mm2

250 100

50mm2 50mm2 50mm2 50mm2 70mm2

300 60

50mm2 50mm2 50mm2 70mm2 70mm2

350 100

70mm2 70mm2 70mm2 70mm2 95mm2

350 60

70mm2 70mm2 70mm2 70mm2 95mm2

400 60

70mm2

70mm2

70mm2

95mm2 120mm2

400 100

70mm2

95mm2

95mm2

95mm2 120mm2

500 60

70mm2

70mm2

95mm2

95mm2 120mm2

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require

cables larger than recommended, or cables rated higher than 167°F(75°C).

Negative Electrode Polarity

The Power Feed 84 ships from the factory configured for

electrode positive polarity. See P.81 in the Operations

Section (Set-Up menu) to select negative polarity

welding.