Diagnostic Information

2-17

5050-001

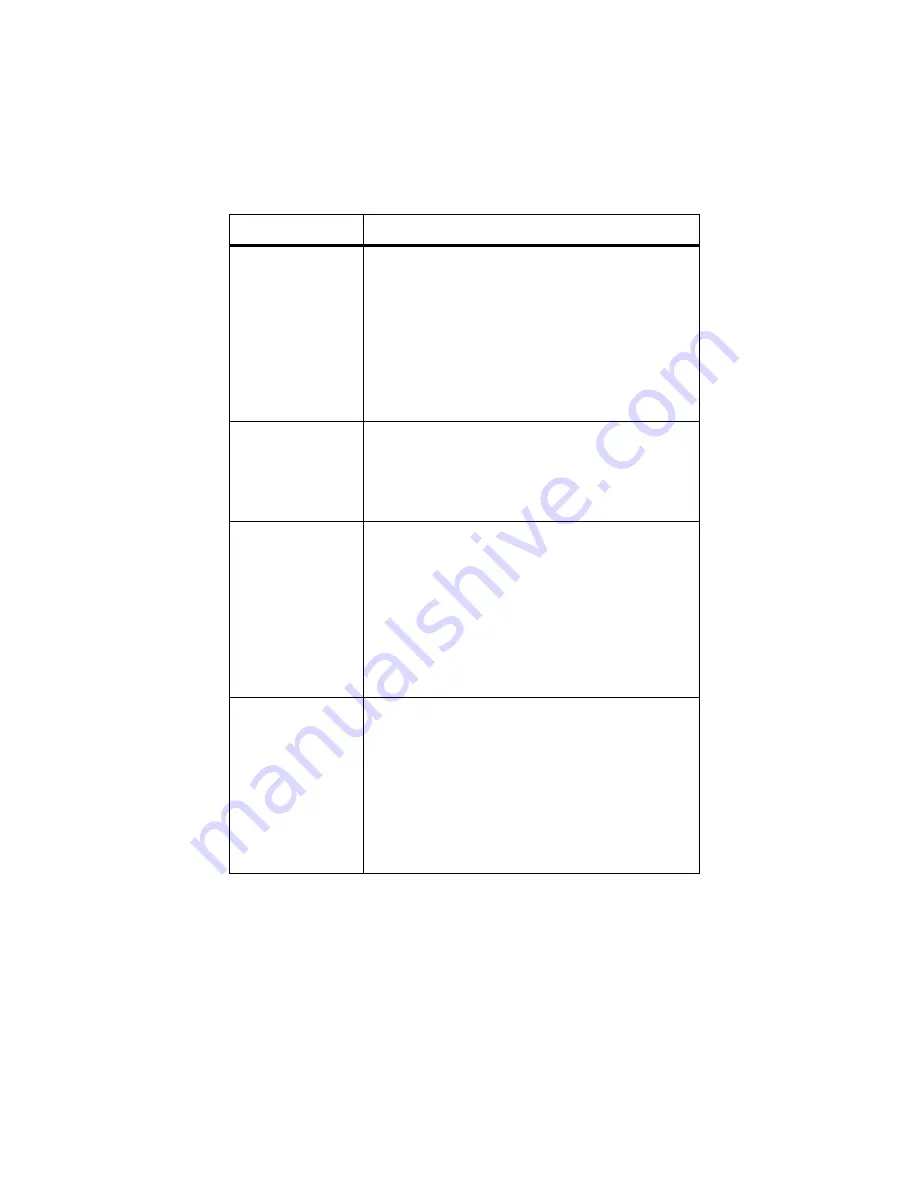

52 Flash Full

There is not enough space available to hold the

resources you want to store in flash memory.

• Press

Go

to clear the message and continue

processing. Downloaded fonts and macros not

previously stored in flash memory or disk are

deleted.

• Reset the printer. Press

Menu>

or

<Menu

. The Job

Menu is displayed. Press

Menu>

or

<Menu

until

Reset Printer appears on the second line. Press

Select

.

53 Unformatted

Flash

The flash memory installed in your printer has not

been formatted. You must format the flash memory

before downloading resources.

Press

Go

to clear the message. To format flash

memory, select Format Flash from the Tests Menu.

54 Parallel Error

The printer has detected a protocol error on the

standard parallel interface. Check the cable

connection between the printer and the computer, and

make sure the cable is not defective.

• Press

Go

to clear the message and continue

printing. The job may not print correctly.

• Reset the printer. Press

Menu>

or

<Menu

. The Job

Menu is displayed. Press

Menu>

or

<Menu

until

Reset Printer appears on the second line. Press

Select

.

54 Parallel Option

x

Error

The printer has detected a protocol error on the

specified parallel interface. Check the cable

connection between the printer and the computer, and

make sure the cable is not defective.

• Press

Go

to clear the message and continue

printing. The job may not print correctly.

• Reset the printer. Press

Menu>

or

<Menu

. The Job

Menu is displayed. Press

Menu>

or

<Menu

until

Reset Printer appears on the second line. Press

Select.

Message

Action

Summary of Contents for Optra Color 1200

Page 18: ...General Information 1 7 5050 001...

Page 20: ...General Information 1 9 5050 001...

Page 26: ...General Information 1 15 5050 001...

Page 33: ...General Information 1 22 5050 001...

Page 35: ...General Information 1 24 5050 001...

Page 36: ...General Information 1 25 5050 001 Paper Path for Mono Pages Paper Path for Color Pages...

Page 113: ...3 28 5050 001 Print Quality Test Page...

Page 114: ...Diagnostic Aids 3 29 5050 001 Print Quality Test Page...

Page 129: ...Repair Information 4 15 5050 001 Cover Removals...

Page 149: ...Repair Information 4 35 5050 001 4 Remove the temperature fuse silver screw with washer...

Page 152: ...4 38 Service Manual 5050 001 5 Open the guide retainer 6 Remove the press roller...

Page 163: ...Repair Information 4 49 5050 001 6 Remove the drum gear sensor 2 black screws...

Page 183: ...Connector Locations 5 1 5050 001 5 Connector Locations Paper Handling...

Page 185: ...Connector Locations 5 3 5050 001...

Page 187: ...Connector Locations 5 5 5050 001 Electrical Components...

Page 188: ...Connector Locations 5 6 5050 001 Sensors...

Page 189: ...Connector Locations 5 7 5050 001 Power Supply Board 614 MPS E...

Page 190: ...Connector Locations 5 8 5050 001 High Voltage Unit 1 Board 614 HVU1...

Page 191: ...Connector Locations 5 9 5050 001 High Voltage Unit 2 Board P614 HVU2...

Page 192: ...Connector Locations 5 10 5050 001 Optional Paper Feed Controller Board P614 2 3 DRIV...

Page 193: ...Connector Locations 5 11 5050 001 Printhead Controller Board P614 HD CONT...

Page 194: ...Connector Locations 5 12 5050 001 Printer Controller Board P614 PRCONT...

Page 195: ...Connector Locations 5 13 5050 001 Size Sensor Board P611 PSZ...

Page 196: ...5 14 Service Manual 5050 001 RIP Controller Card...

Page 200: ...Parts Catalog 7 2 5050 001 Assembly 1 Covers...

Page 202: ...Parts Catalog 7 4 5050 001 Assembly 1 cont Covers...

Page 204: ...Parts Catalog 7 6 5050 001 Assembly 2 Paper Exit...

Page 206: ...Parts Catalog 7 8 5050 001 Assembly 3 Upper Unit...

Page 208: ...Parts Catalog 7 10 5050 001 Assembly 4 Base 1...

Page 210: ...Parts Catalog 7 12 5050 001 Assembly 5 Base 2...

Page 212: ...Parts Catalog 7 14 5050 001 Assembly 5 cont Base 2...

Page 214: ...Parts Catalog 7 16 5050 001 Assembly 5 cont...

Page 216: ...Parts Catalog 7 18 5050 001 Assembly 6 Feeder...

Page 218: ...Parts Catalog 7 20 5050 001 Assembly 6 cont Feeder...

Page 220: ...Parts Catalog 7 22 5050 001 Assembly 7 Electrical...

Page 222: ...Parts Catalog 7 24 5050 001 Assembly 7 cont Electrical...

Page 224: ...Parts Catalog 7 26 5050 001 Assembly 8 I F Controller...

Page 226: ...Parts Catalog 7 28 5050 001 Assembly 9 Fuser...

Page 228: ...Parts Catalog 7 30 5050 001 Assembly 9 cont Fuser...

Page 230: ...Parts Catalog 7 32 5050 001 Assembly 10 Cassette...

Page 232: ...Parts Catalog 7 34 5050 001 Assembly 11 Optional Feeder Base...

Page 234: ...Parts Catalog 7 36 5050 001 Assembly 11 cont Optional Feeder Base...

Page 236: ...Parts Catalog 7 38 5050 001 Assembly 12 Optional Feeder Paper Feed...

Page 238: ...Parts Catalog 7 40 5050 001 Assembly 13 Optional Features...

Page 244: ......

Page 245: ......