Page that jammed does not reprint

after you clear the jam

Cause

Solution

Jam Recovery in the Setup menu

is set to Off.

Set Jam Recovery to Auto or On:

1

Press

.

2

Press

until

Settings

appears, and

then press

.

3

Press

until

Setup

Menu

appears, and then

press

.

4

Press

until

Recovery

appears, and

then press

.

5

Press

until

Jam

Recovery

appears, and

then press

.

6

Press

until

On

or

Auto appears, and then

press

.

Solving print quality problems

Isolating print quality problems

To help isolate print quality problems, print the print quality test

pages:

1

Turn the printer off.

2

From the control panel, press and hold

and while

turning the printer on.

3

Release both buttons when

Performing Self Test

appears.

The printer performs its power-on sequence, and then

CONFIG MENU

appears.

4

Press

until

Prt Quality Pgs

appears, and then press

.

The pages are formatted.

Printing Quality Test

Pages

appears, and then the pages print. The message

remains on the control panel until all the pages print.

5

After the print quality test pages print, press

until

Exit

Config Menu

appears, and then press

.

The information in the following topics may help you solve print

quality problems. If these suggestions still do not correct the

problem, contact Customer Support. You may have a printer part

that requires adjustment or replacement.

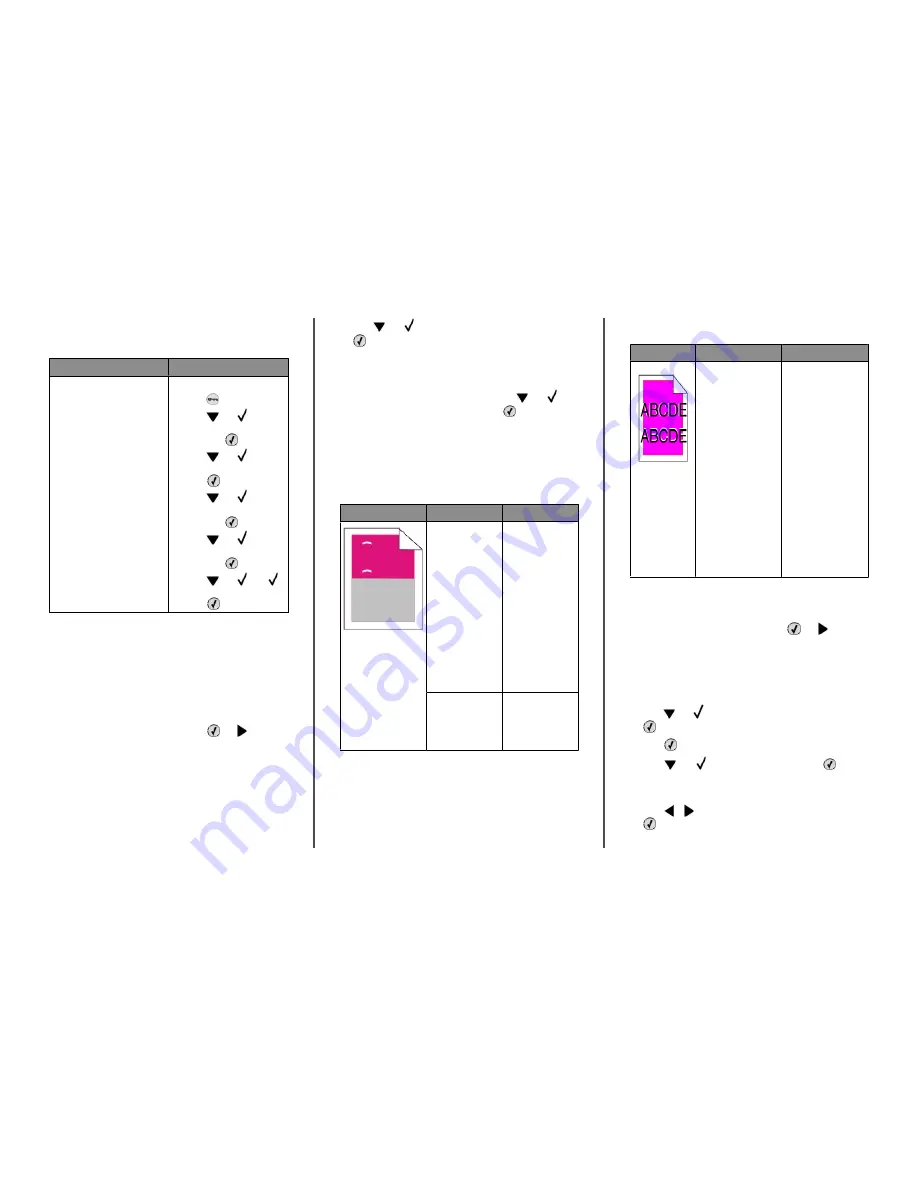

Repeating defects

Example

Cause

Solution

If marks occur

repeatedly only in

one color and

multiple times

down a page, a

toner cartridge or

photoconductor

may be defective.

Replace the toner

cartridge if the

defects occur every:

•

33.5 mm

(1.32 in.)

•

35.7 mm

(1.41 in.)

Replace the

photoconductor if

the defects occur

every:

•

28.3 mm

(1.11 in.)

•

72.4 mm

(2.85 in.)

If marks occur down

the page

repeatedly in all

colors, the fuser

may be defective.

Replace the fuser if

the defects occur

every 116.2 mm

(4.58 in.).

Color misregistration

Example

Cause

Solution

Color has shifted

outside of the

appropriate area or

has been

superimposed over

another color area.

•

Adjust the color

alignment. For

more information,

see “Adjusting the

color alignment”

on page 4.

•

Remove and

reinstall the

photoconductors.

For more

information about

installing supplies,

see the

User's

Guide

on the

Software and

Documentation

CD.

Note: If you have not

resolved the issue,

adjust the color

alignment again.

Adjusting the color alignment

1

Make sure the printer is turned off.

2

From the control panel, press and hold

and while

turning the printer on.

3

Release both buttons when

Performing Self Test

appears.

The printer performs its power-on sequence, and then

CONFIG MENU

appears.

4

Press

until

Color Alignment

appears, and then press

.

5

Press

again to print the alignment page.

6

Press

until

Set A

appears, and then press

.

7

From the printed sheet, find the straightest of the 20 lines

beside the letter A.

8

Press or until that number is displayed, and then press

.

Submitting Selection

appears.

4